ALUMESS.easyloc – FIXTURING SYSTEM FOR LASER MACHINING

ALUMESS.easyloc – FIXTURING SYSTEM FOR LASER MACHINING

ALUMESS.easyloc – modular fixturing system for laser marking, laser engraving and laser welding. Workpieces can leave production perfectly marked.

ALUMESS.easyloc – Fixturing and palletizing system for laser machining

Our ALUMESS.easyloc sets for laser machining are the only ready-to-use, quickly exchangeable, modular fixturing systems for laser marking, laser engraving and laser welding.

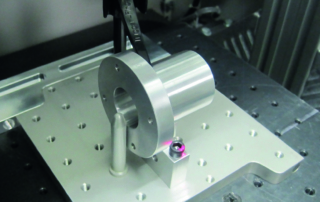

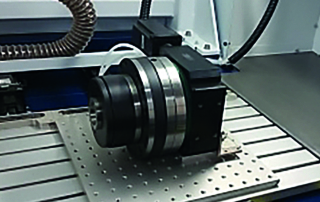

Parts can be quickly and easily fixed on pallets with V-groove or pocketed-trays. Addtionally our pallets can be assembled with a various range of fixturing-sets, clamping components to insure a safe fixturing of the workpieces. These fixturings can be at any time completed with customized or workpiece-specific fixturings. Profits are in the speed of the swap.

ADVANTAGES

- is the only ready-to-use, quickly exchangeable, modular fixturing systems for laser marking, laser engraving and laser welding.

- Can be easily installed on any equipment

- Speeds up your process so you can mark more workpieces per shift

- Is risk-free – if it isn’t what you want, simply return for a full refund

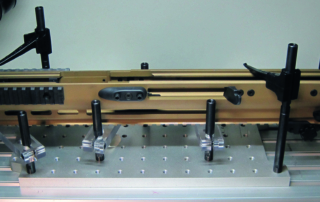

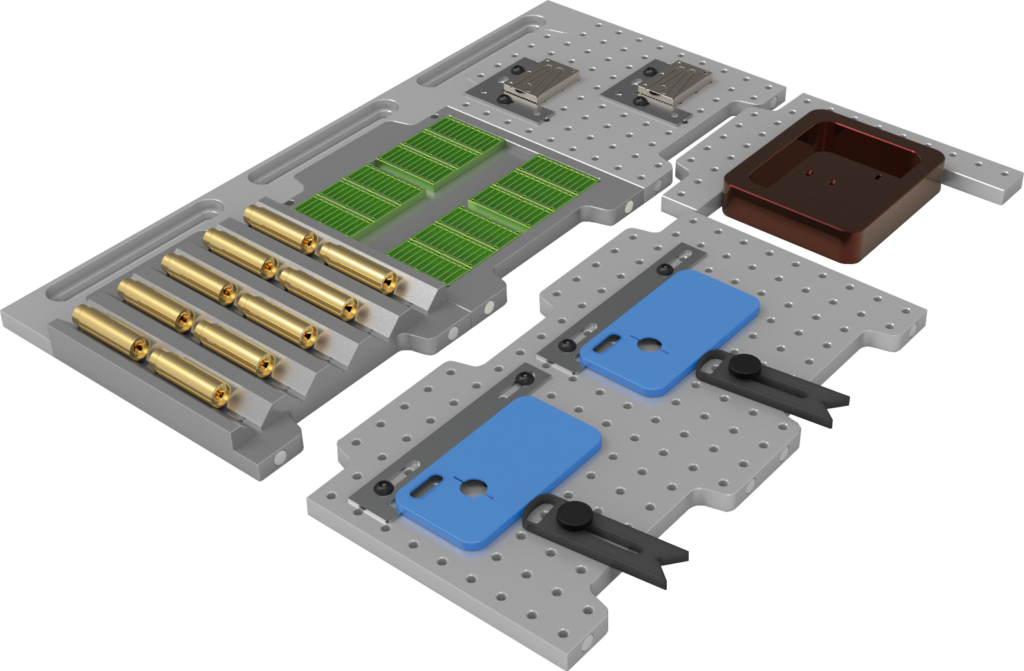

Pallet and clamping device combination option

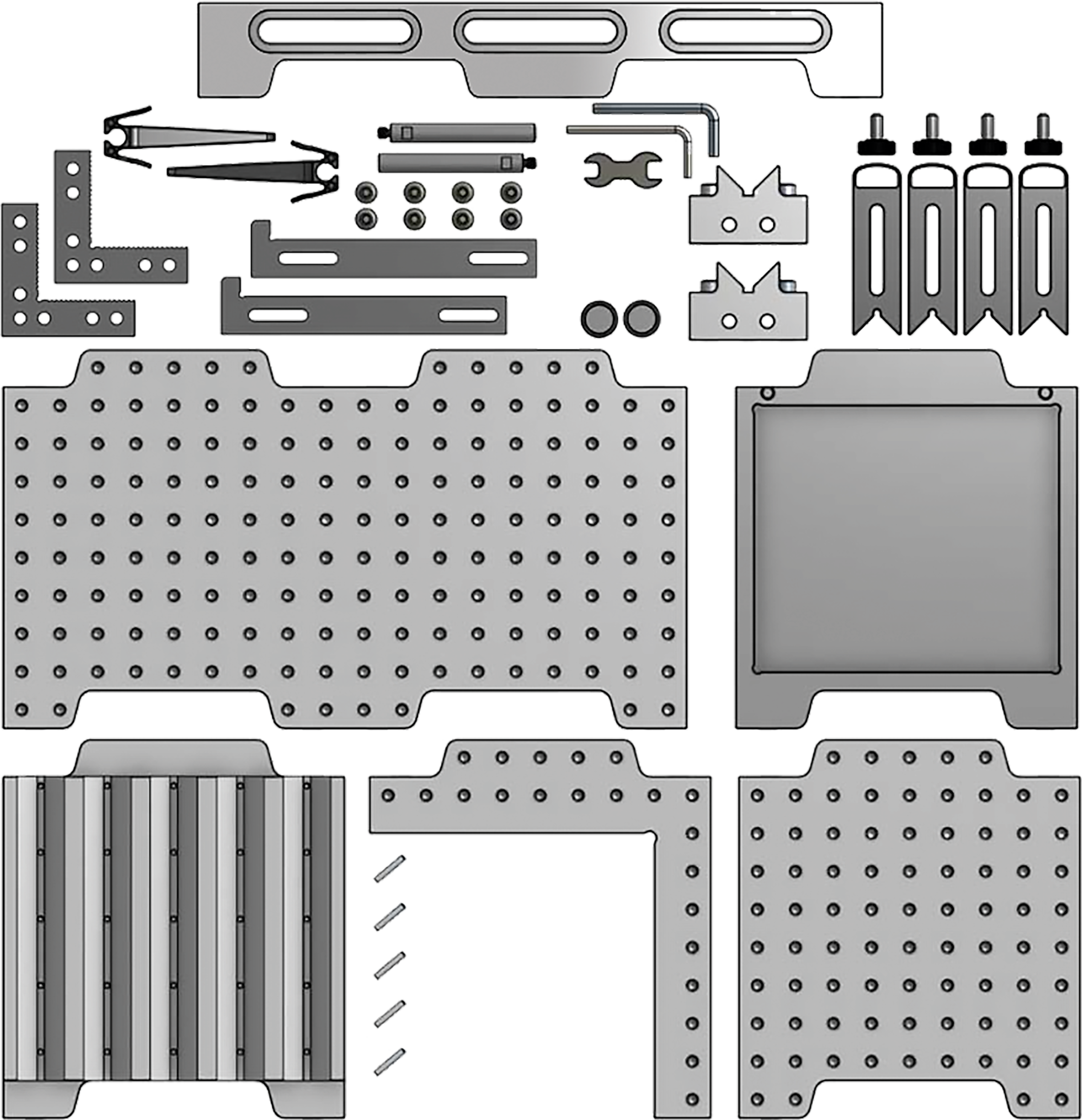

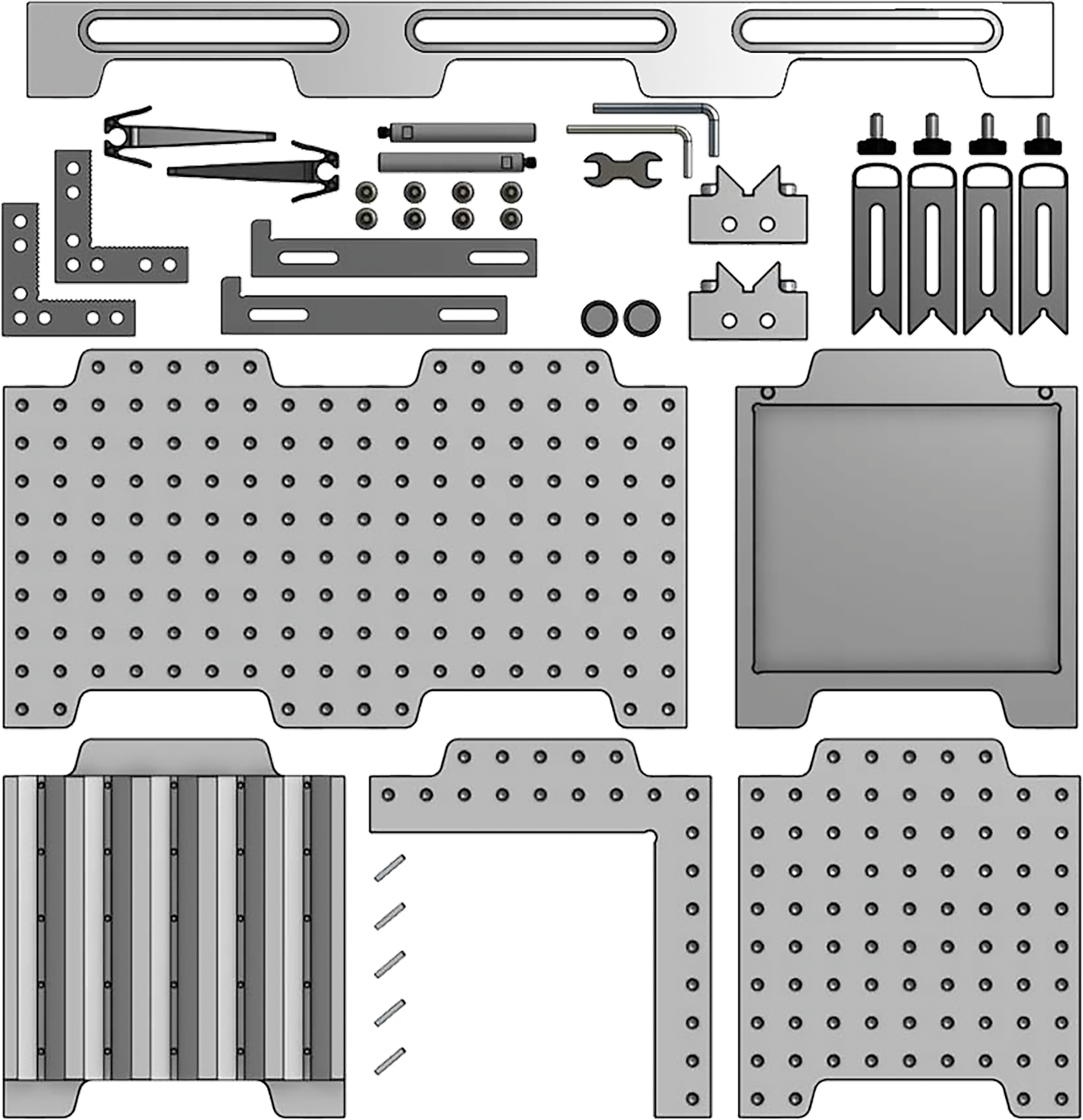

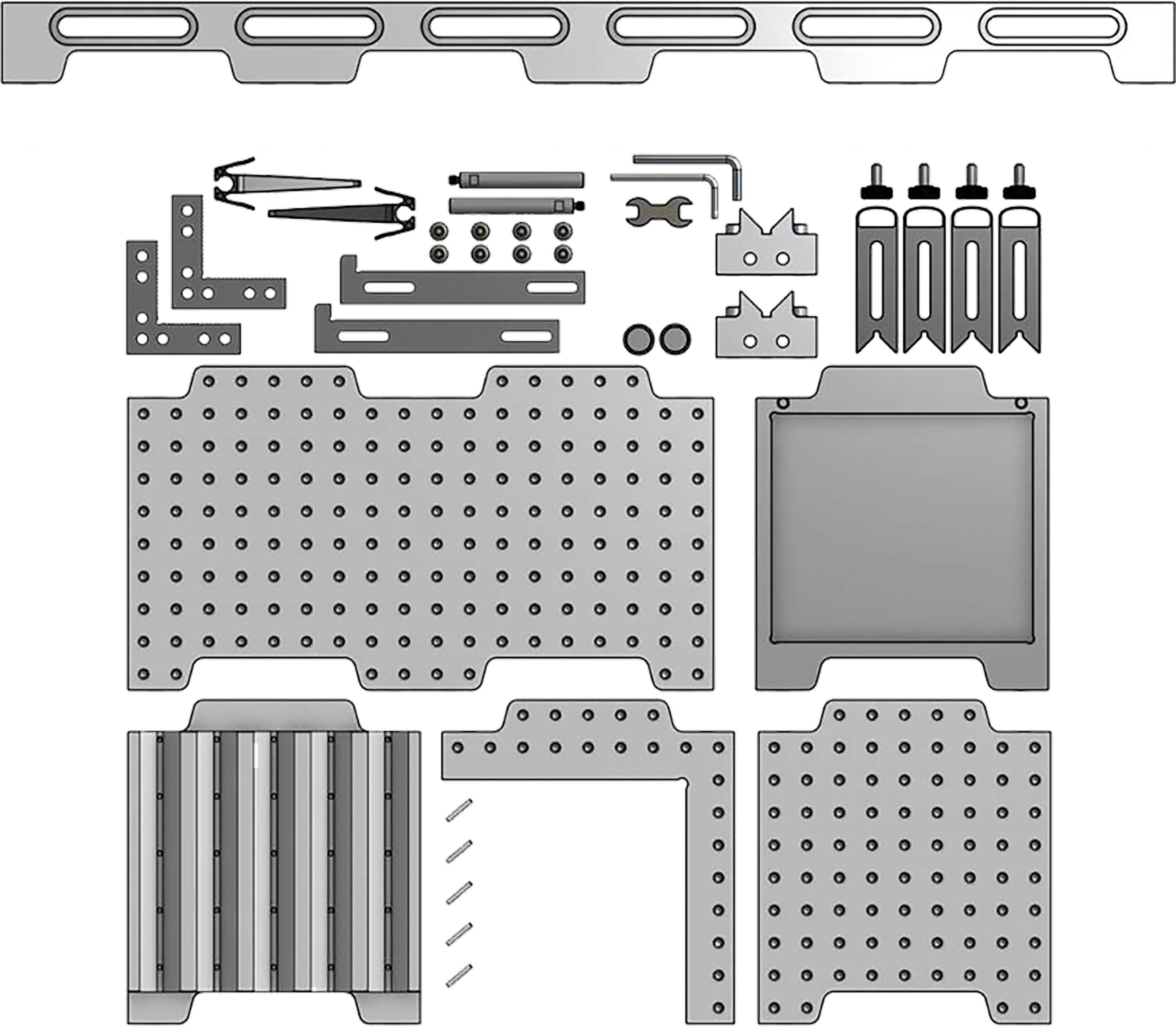

ALUMESS.easyloc starter-kits for laser machining

Our ALUMESS.easyloc sets for laser marking systems are the only universal, easy-to-use and ready-made quick-swap fixture system for laser marking applications and laser engraving.

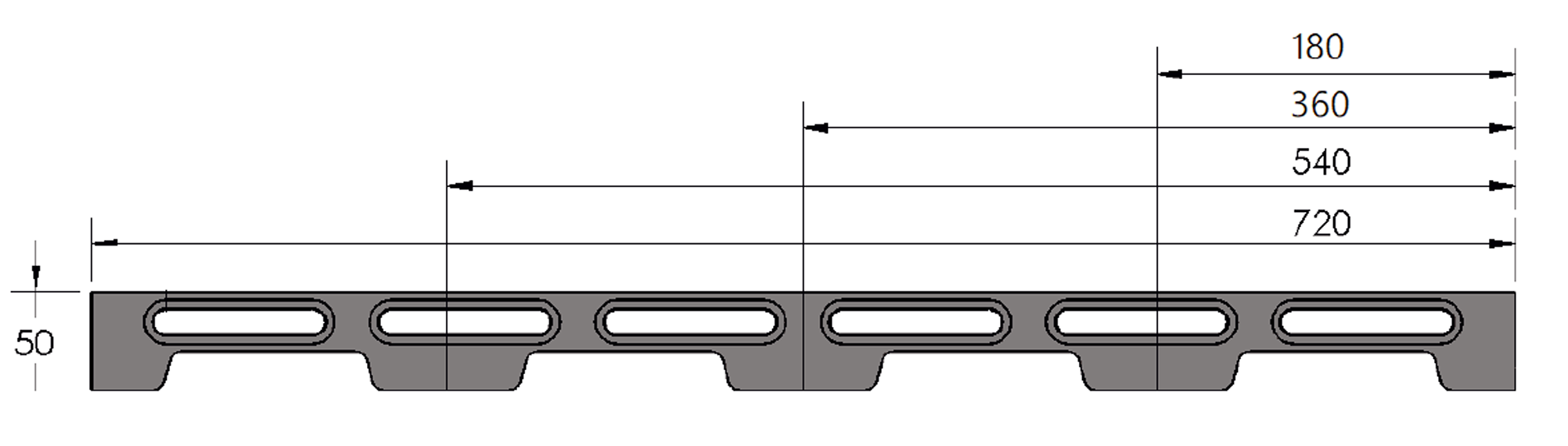

They can be configured easily, individually and machine-specifically. The suitable docking rail is mounted on the laser marking system. The magnetic, interlocking quick-swap pallets hold the workpieces using universal fixing elements.

In the future, equipping the system will be child‘s play.

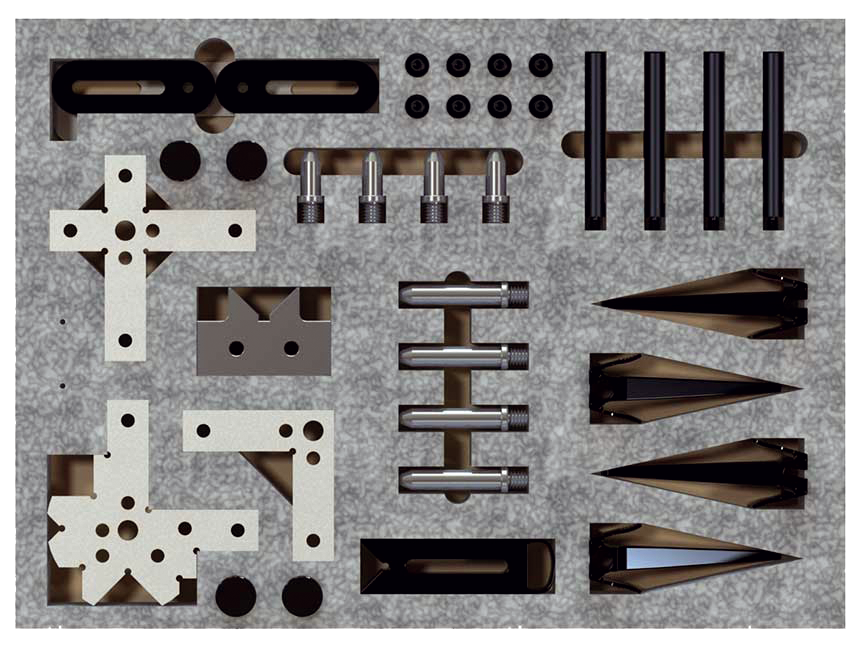

Alumess.easyloc laser set (inch-version) in 5S foam organizer

ALUMESS.easyloc extension – workholding kit LA

- laser marking

- laser engraving

- laser welding

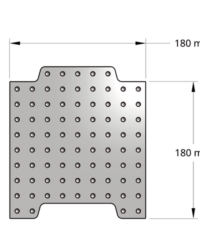

Technical data

- Pallet dimensions: Height 12,7 mm

- Grid pattern: 20×20 mm

- Thread: M6

System advantages

- Simplest assembly

- Changeover in seconds

- Fixation according to contour

- Flexible combinable

Basic components

Assembly examples ALUMESS.easyloc fixturing device

Our ALUMESS.easyloc starter kits for laser machining

ALUMESS.easyloc – a case study

Continuous improvement is fostered in the culture at Armstrong International of Three Rivers, Michigan. The company’s longevity – more than 115 years in business – is a reflection of this culture. One recent improvement was made in the identification process for the stainless steel line which tens of thousands of product variations totaling more than 115,000 parts are manufactured per year. The part marking process may seem like an insignificant step to examine, however in the case of Armstrong, not only has the improvement saved them countless dollars, it resulted in better service for their customers.

WHAT CAN WE DO FOR YOU?

By using our products and services, our customers increase the productivity of their production by up to 100% and at the same time reduce their production costs to a large extent.