EDM

Clamping elements for the EDM sector

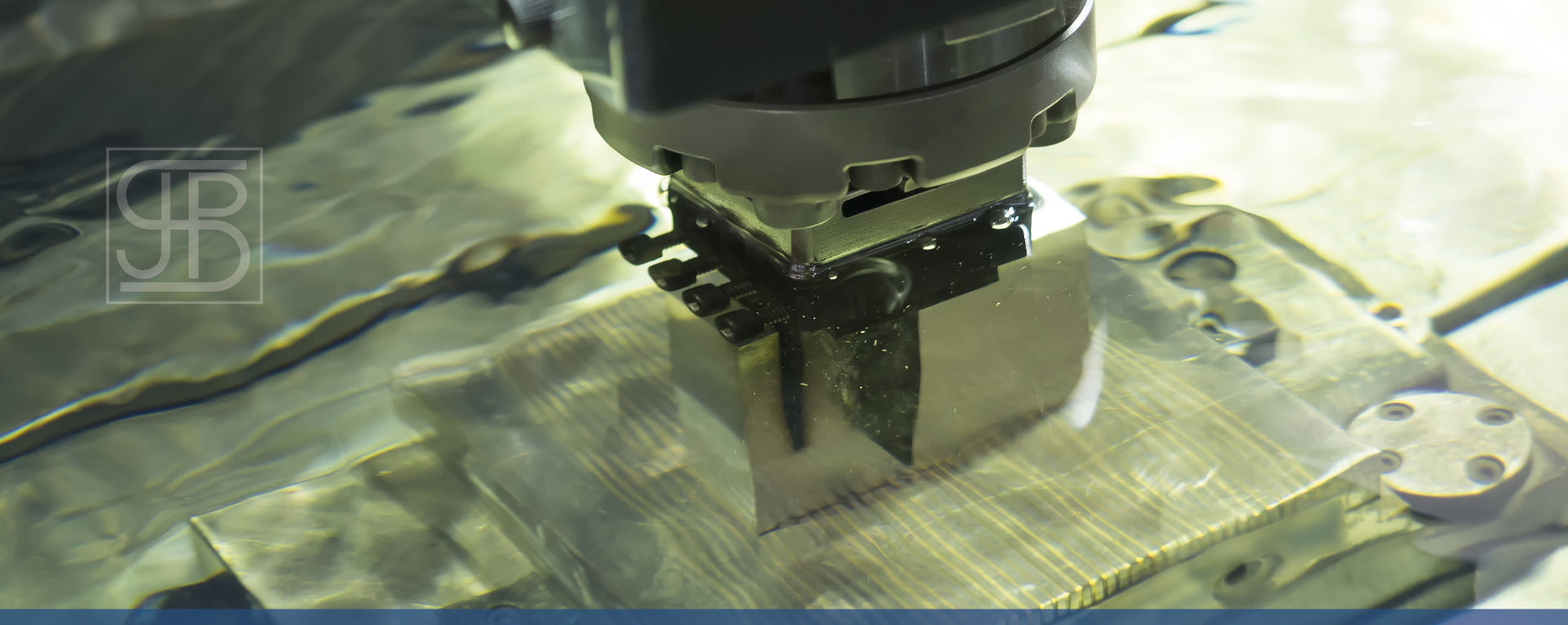

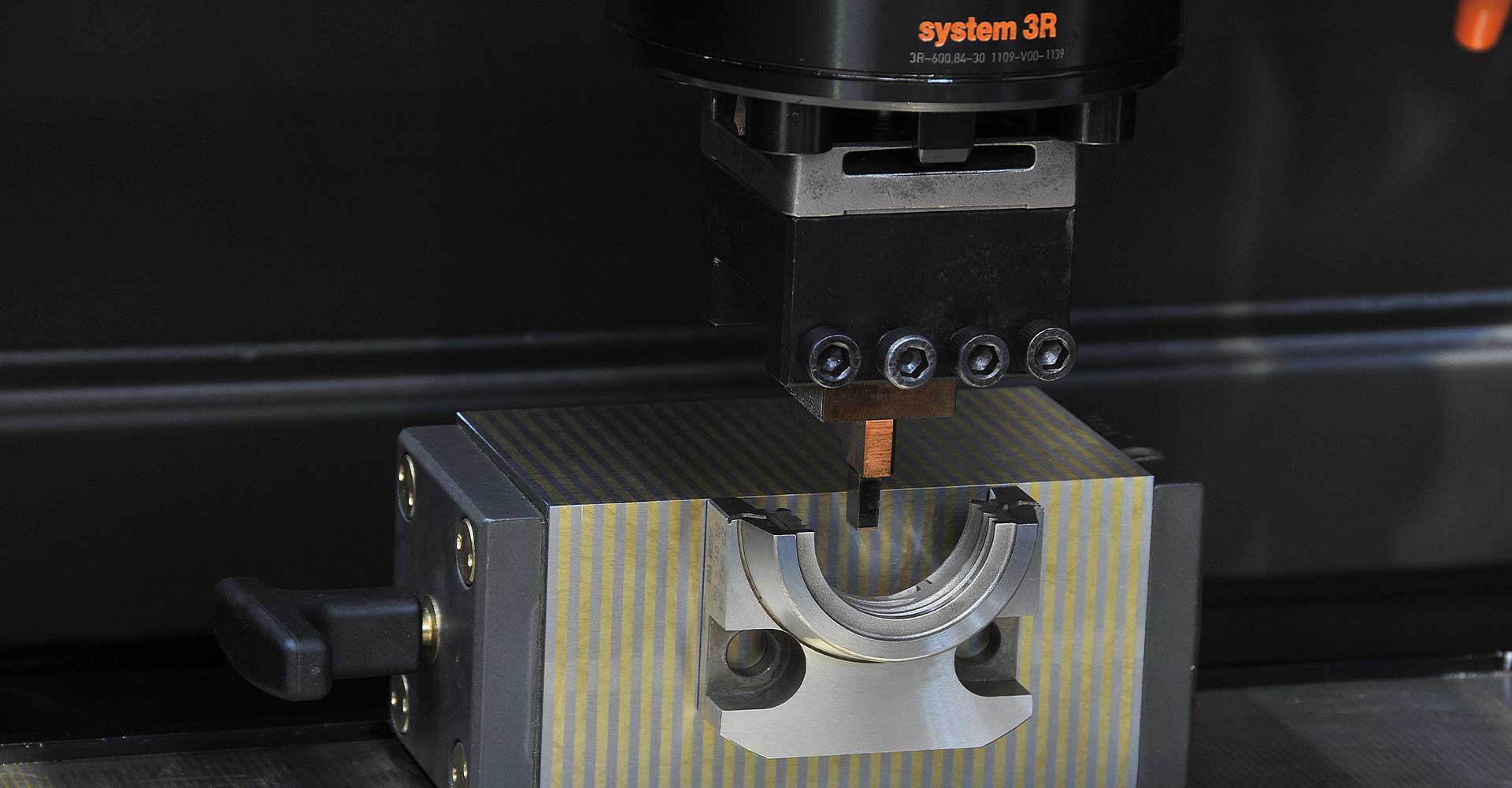

EDM is an electroerosive material removal process, which is divided into the three main areas, drilling, wire-cutting or die-sinking EDM. Although a barely measurable force is exerted between the electrode and the workpiece, precise and repeatable positioning and clamping of the workpieces is nevertheless a basic prerequisite for maintaining the finest tolerance fields. Due to a wealth of experience of many decades, which is accompanied by permanent further development, SPREITZER can present solutions today that meet the highest requirements.

Depending on the EDM process and workpiece design, different clamping systems can be used. This includes, especially in die-sinking EDM, the universal clamping system, which, through extensions as a modular system, offers limitless application possibilities.

Application areas EDM

WHAT CAN WE DO FOR YOU?

Our products are developed and produced for numerous applications in the manufacturing industry. Our large know-how enables us to offer you the perfect solution for your application. Quality and efficiency are always in the foreground.