BAR-MARKING-MACHINE

BAR-MARKING-MACHINE

(also known as bar embossing machine, roller embossing machine, roll-off embossing machine or hexagonal embossing machine).

Endless marking by roller embossing

The SPREITZER endless bar-marking-machine makes quality traceable. The bar-marking-machine is used for economical and fast continuous stamping of bar material before the actual processing of the production order on the CNC machining center. Before processing, the material batch is stamped with a product- or company-specific marking. Subsequently, each component leaves the production line marked. This means that the product quality of the material batch can be tracked throughout the product’s service life via a product- or company-specific label.

We would like to particularly recommend the following strengths of the bar marking machine:

- Super fast, embossed material identification

- Short setting and changeover times

- Robust and maintenance free

- CE compliant design with safety features

The embossing pressure and the embossing depth that can be made by the bar marking machine can be set and adjusted via a threaded spindle by means of a handwheel, depending on the bar material or material quality.

In setup mode, the transport/embossing speed of the embossing machine can be continuously reduced to a minimum. The built-in soft start in automatic mode, emergency stop switch, signal light as well as signal sound protects the employees during the daily handling of this roller embossing machine.

ENDLESS BAR-MARKING-MACHINE

Roller stamping machines from SPREITZER

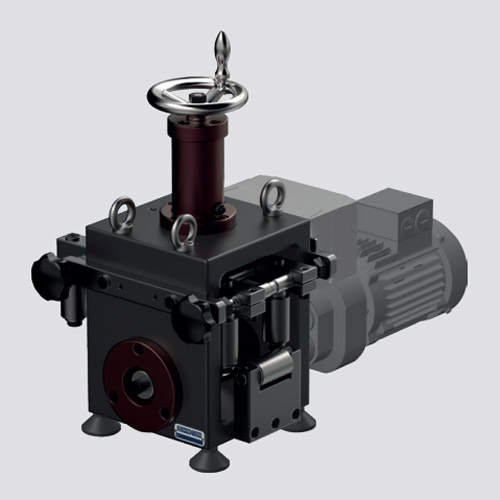

Bar-marking-machine with motor

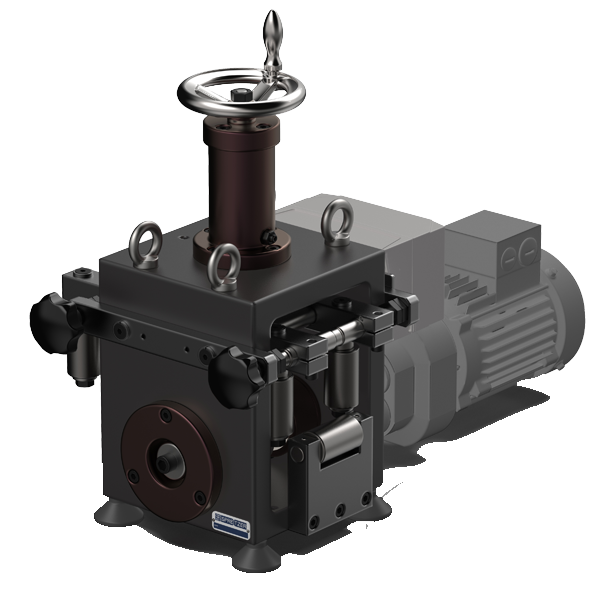

Bar-marking-machine without motor

Technical data:

- Material passage: 1-70 mm (1-90 mm)

- Throughput speed: 16.5 m/min

- Roll dimension: Ø 72/30×20 mm

- Max. Roller diameter: 75 mm

- Driving power: 0.37 KW-0.5 HP

- Max. Torque: 49 Nm

- Spindle speed: 73 min-1

- Operating voltage: 400 V – 50 Hz

- Current consumption: 1.1 A

- Protection class: IP 44

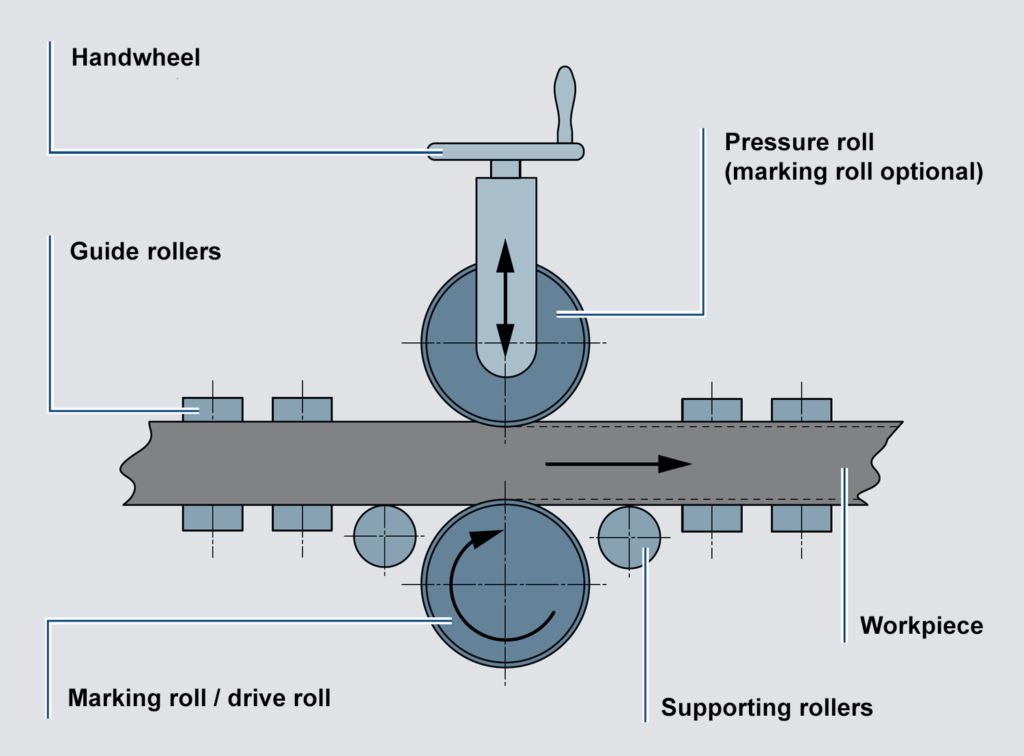

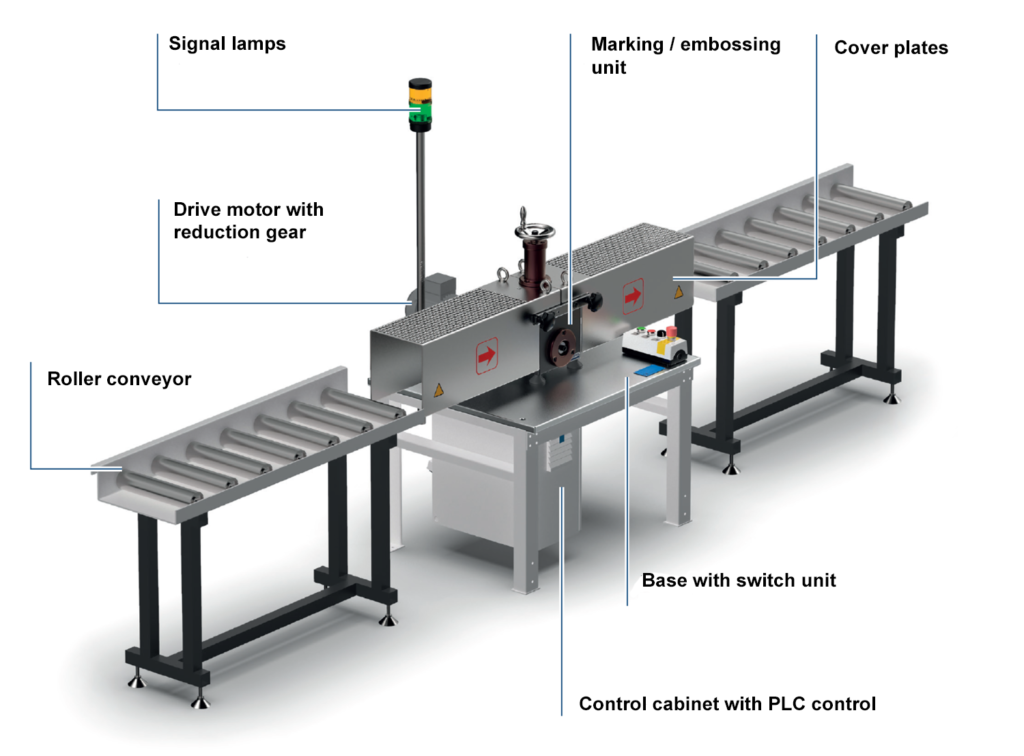

Function endless bar-marking-machine ESS 70

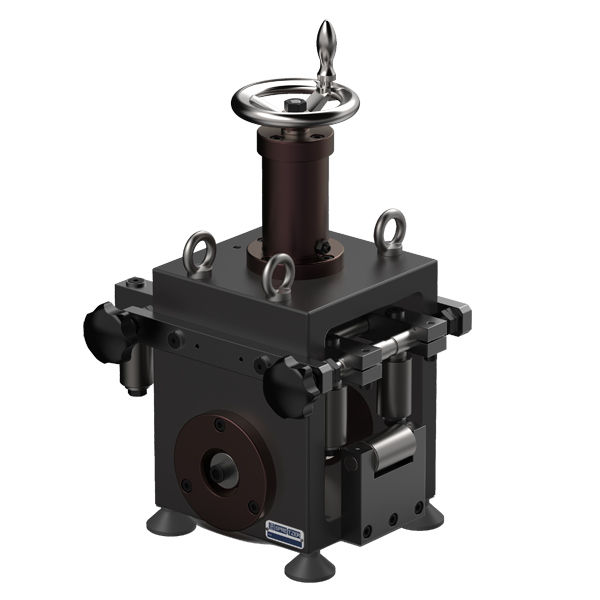

The roller-bearing spindle, removable counter bearing, adjustable pressure roller, and horizontal and vertical guide rollers are built into a strong machine body of the marking/embossing unit.

A robust geared motor with a reduction ratio of 1:20 drives the drive spindle. The replaceable marking rollers are force-fitted on the spindle.

The adjustable embossing pressure is safely absorbed by an additional counter bearing. The pressure roller is mounted adjustably in a quill. The embossing pressure and the embossing depth can be set and adjusted via a threaded spindle by means of a handwheel, depending on the bar material or material quality.

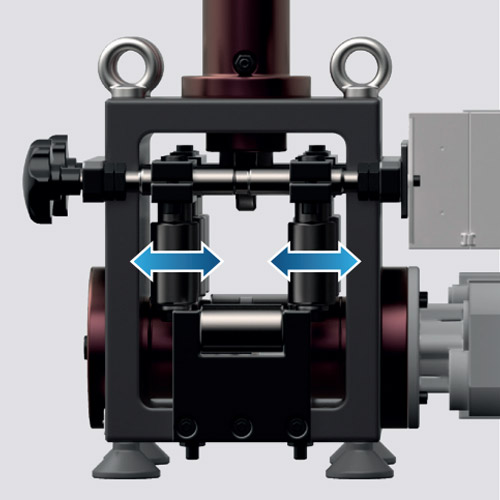

The engraved, driven marking roller pulls the material bar through the machine. The lateral material guide is provided by two pairs of guide rollers, each of which can be adjusted centrally to the marking roller via threaded spindles.

Two fixed bearing blocks with support rollers are provided for horizontal guidance. All guide rollers are mounted by means of maintenance-free plain bearings. Overall, the machine is designed in such a way that only very short setting and changeover times are required. In setup mode, the transport / embossing speed can be continuously reduced to a minimum. The built-in soft start in automatic mode, emergency stop switch, signal light as well as signal tone protect the employees during daily handling of the machine.

Upon request, the table version of the bar-marking-machine can also be equipped with a stable base.

YOUR PARTNER WITH QUALITY

Your proven partner within turnkey solutions. Custom-made fixtures in original equipment quality since 1983. You can benefit from our many years of experience!