CNC CONTRACT MANUFACTURING, CONTRACT MANUFACTURING

We offer you our extensive machinery as an “extended workbench”. We manufacture spare parts for your machines and production systems quickly and easily. The production of individual parts and small series, as well as assemblies for machine and tool construction or precision mechanics are our strength.

MANUFACTURING ENVIRONMENT

We have modern CNC production technologies, automation systems and experienced skilled workers. Benefit from the large vertical range of manufacture and the resulting short lead times.

+ Strengths:

- Competence through years of experience

- Efficiency through modern manufacturing technologies

- Flexibility through automated production processes

- Quality through professionalism

- Short lead times through high vertical range of manufacture

Production capacities

- 3D CAD design

- CAD/CAM programming and simulation

- CNC turning

- CNC milling / 3, 4 and 5 axes

- CNC surface grinding

- CNC wire eroding

- CNC die-sinking EDM

- CNC coordinate measuring

- Deep hole drilling

- Surface grinding

- Cylindrical grinding / thread grinding

- Coordinate grinding

- Vacuum plasma nitriding

- Surface and heat treatments

- Assembly / Service

MANUFACTURING PROCESSES

Competitive production

- Economical production of high-quality components

- Efficient production

- Shorter delivery times through new thinking in all planning and production areas

- Contract manufacturing with high flexibility, productivity and transparency from batch size one onwards

Networking

- Production of complex parts on CNC machines

- All production-relevant geometry data from the CAD model to the CNC programming in a constant network through DNC networking

- Minimisation of set-up times, especially for single-part production

- Minimisation of transmission errors

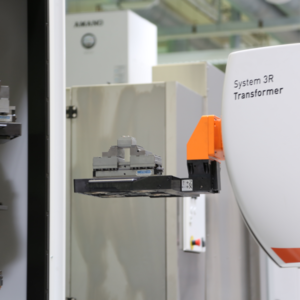

Automation

- AutomationExpanded machine availability through automated manufacturing technology

- Optimised production processes

- Fast response and delivery times

Production control

- Powerful ERP system to control the entire organisation, production planning and order processing.

- MES planning system for managing and optimising all manufacturing departments “in real time

+ Strengths:

- High-quality and modern machinery

- Service for our customers

- Shorter delivery times through networking of CNC machines

- Effective and efficient production

- Real-time production planning through ERP, BDE and MES systems

- Certified according to DIN EN ISO 9001:2015

- Reliability. 100% quality. Made in Germany.

WHAT CAN WE DO FOR YOU?

As an extended workbench for spare parts, individual parts and small series, we are optimally positioned. We can guarantee you on-time delivery, consistent quality and maximum precision.