FREEZE CLAMPING TECHNOLOGY

FREEZE CLAMPING TECHNOLOGY

We offer freeze clamping plates, ice plates for safe and quick fixturing of delicate or non-metallic workpieces. What used to be reserved for aerospace technology can now find its way into your production facility with our help.

INNOVATIVE FREEZE CLAMPING TECHNOLOGY

Ice provides excellent adhesion. Just think of the hoarfrost on windshields on a winter morning or the ice tray stucked in the freezer compartment of the refrigerator.

Freeze clamping technology is a powerful system that takes advantage of this property.

ADVANTAGES FREEZE CLAMPING TECHNOLOGY

The sensitive parts are clamped without pressure – deformations and fractures occurring when clamping workpieces are avoided.

Without special pre-machining and regardless of their shape, the parts can be clamped on only one side.

In addition, five-axis machining is possible for each operation. Ice can be used to “hold” a wide variety of hard and soft materials: Metal, plastics, ceramics, graphite, glass, rubber, neoprene, textiles, etc.

Clamping with freezing technique:

- Clamping without deformation

- Clamping without force influence on sensitive workpieces

- Clamping of smallest workpieces

After loosening/thawing the workpieces, the ice offers the advantage that no residue remains on the workpiece.

>> No residues on the workpiece

High holding force

For a metallic workpiece, the nominal holding force of the freeze clamping plate is 150 N/cm².

Compared:

- 100-150N/cm² for magnetic chucks

- 10 N/cm² for vacuum chucks

APPLICATION

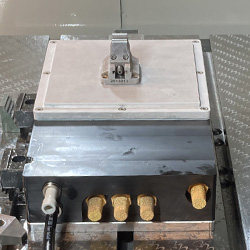

The compact freeze clamping plates / ice plates are made of one piece and can be used very quickly:

- Connect the device to the compressed air supply (clean, dry compressed air).

- Spray water on the freezer plate

- Place workpiece

- Operate lever for icing or defrosting

WHAT CAN WE DO FOR YOU?

By using our products and services, our customers increase the productivity of their production by up to 100% and at the same time reduce their production costs to a large extent.