CUSTOM-MADE CLAMPING FIXTURES

CUSTOM-MADE CLAMPING FIXTURES

Experience and know-how since 1983 from SPREITZER in custom-made fixture construction

“Special is not a foreign word for us, but a challenge”.

We develop and produce high-precision, customized special devices with decades of experience exclusively in Gosheim, Germany. From the idea, through development and production, to assembly and final testing We rely on short distances and experienced and trained employees. Our international customers appreciate the long-lasting quality of our special constructions. We are a reliable partner in the implementation of your individual requirements.

Guaranteed increase in productivity through solid custom work.

SPREITZER plans, develops and manufactures high-quality clamping fixtures according to the individual application and requirements of the customers.

PERFORMANCE

- Competence and experience in implementation

- Perfectly coordinated fixture concept

- Open, uncomplicated and close cooperation

- Fast implementation

- Quality and durability of our clamping devices

- Concrete improvements in flexibility, manufacturing quality and productivity

- Maximum success at the optimum price/performance ratio

PROJECT MANAGEMENT

Customer-oriented thinking and acting is always of great importance during the elaboration as well as the support of a project. Each project receives equal attention to service and commitment to customer satisfaction. We offer project management from feasibility study to full commissioning. Quality is monitored at every stage of development and production. Quality checks and final tests are also carried out before the project is delivered. The offer is submitted by means of a design sketch, the scheduling is done after consultation with the customer. Once the order has been placed, the “start-up discussion” serves as the basis for the success of the project. Details are discussed and recorded here.

PROCESSES

Process schema

MANUFACTURING PROCESSES – EFFICIENT PROCESS CHAIN

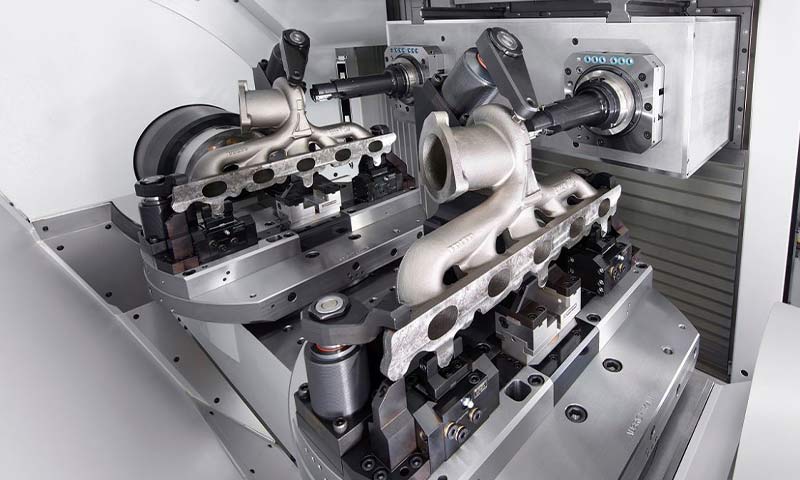

CUSTOM-MADE CLAMPING DEVICES

Guaranteed increase in productivity through solid custom work

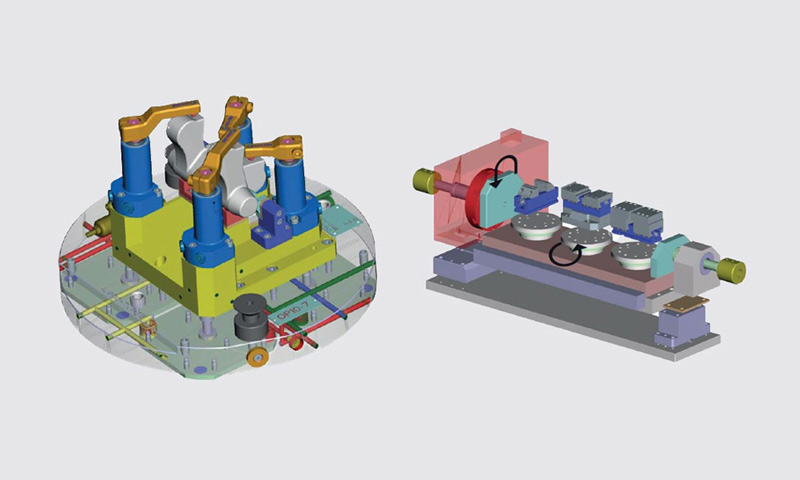

SPREITZER plans, develops and manufactures high quality fixtures according to the individual purpose and needs of the customer. Our core competence lies in mechanical, pneumatic and hydraulic

- Custom-made clamping devices for machining centers and special machines

- Custom-made clamping devices on rotary transfer machining centers

- Drilling jigs

Depending on the application, we supply special clamping fixtures together with matching NC rotary table and counter bearing forcomplete machining on modern processing machines .Furthermore we can supply the following:

- Welding fixtures

- Grinding jigs

- Measuring and testing devices

- Mounting devices

INDIVIDUAL ADDITIONAL FUNCTIONS

Due to increased demands on clamping fixtures and clamping devices in use on automated production solutions, we offer customer-specific

additional functions.

Options:

- Workpiece insertion chicanes

- Workpiece support and system control / Airsensoring

- Workpiece support and system cleaning

- Adjustable clamping position

- Tunable clamping position

- Swivel clamping position

- Workpiece press-on handling

“We supply your custom-made clamping device in OEM quality”.

Proven partner within turnkey solutions

SPREITZER has been used as a professional partner within turnkey solutions of different machine manufacturers since 1983. We supply perfect custom-made clamping devices for a safe production process. Benefit from our many years of project experience, our expertise as well as reliable detailed solutions and innovations.

Trust and discretion

Confidentiality and discretion are the prerequisites for a long-term and trusting customer relationship in the project business. We therefore take this request from our customers very seriously and only publish information that has been explicitly released. We ask for your understanding for this. References for individual projects are available on request.

INDUSTRY SECTORS

Our satisfied customers include renowned companies from various industries:

- Mechanical and plant engineering

- Toolmaking and foundries

- Automation technology

- Engine and drive technology

- Vehicle construction

- Chassis systems

- Steering and braking systems

- Air conditioning and control technology

- Energy and water supply

- Building technology and fittings

- Electrical appliances and electrical engineering

- Medical Technology

- Aviation

- Watches and measuring instruments

- Furniture design

HYDRAULIC POWER PACK

The performance data as well as the number of clamping circuits are adapted to your requirements. It is possible to integrate an energy-saving storage charging circuit. The electrical control (e.g. pressure switch/ sensors) enables a monitoring function and communication with the machine.

More information upon request.

Economical hydraulic systems = more efficient work + higher profitability.

Energy-efficient, environmentally compatible parts and components are no longer just a question of ecology and the conservation of resources, but above all represent a tough competitive advantage. With our environmentally friendly, green hydraulics series, we offer you many technological options to promote environmentally conscious behavior and increase profitability.

YOUR PARTNER WITH QUALITY

Your proven partner within turnkey solutions. Custom-made fixtures in original equipment quality since 1983. You can benefit from our many years of experience!