MAGNETIC CLAMPING TECHNOLOGY

MAGNETIC CLAMPING TECHNOLOGY

Magnetic clamping technology enable a very fast workpiece-clamping without destortion.

In all fields of metal processing magnetic clmaping chucks can be used.

Both very thin, damageable workpieces and huge, heavy parts can be safely fixed with the various types of magnetic clamping plates. Especially when processing small batches the use of magnetic chucks will pay off as a quick change of the workpieces/parts can be made.

SPREITZER offers permanent magnetic chucks, electromagnetic chucks, electro-permanent magnetic chucks, magnetic round chucks – for every requirement the suitable clamping plate.

MAGNETIC CLAMPING TECHNOLOGY IN METAL PROCESSING

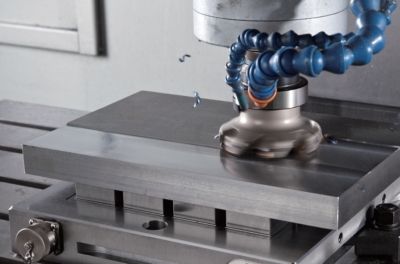

Magnetic clamping technology is used in all areas of metal processing. In grinding, milling, eroding, flat grinding and metrology, magnetic clamping devices prove themselves every day through high precision and durability. The possibility to clamp workpieces fast and most of all distortion-free is one of the important strengths of magnetic chucks.

Our magnetic chucks, magnetic clamping plates can be used as milling magnet, grinding magnet or EDM magnet.

Advantages of magnetic clamping technology:

- Clamping with short setup times

- Flexible and universal

- Large holding forces

- High clamping forces

- Adapted to the workpiece contour

- Precise quality

PERMANENT MAGNETIC CHUCKS

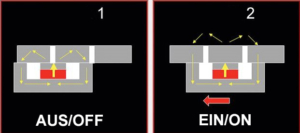

Permanent magnetic clamping technology – the functional principle

The magnetization is achieved by mechanically shifting the poles located inside (North/South) by turning the operating key. In this process, the magnets opposite the north & south poles are arranged in such a way that the magnetic flux lines are diverted across the surface. The stepless holding force generation arises.

The clamping force is consistent, without magnetic leakage and can be adjusted stepplessly.

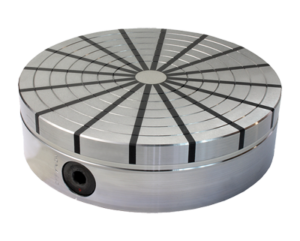

SPREITZER offers rectangular and round permanent magnetic chucks

Both with fine pole pitch for grinding and eroding work and with coarse pole pitch for milling.

- Manually operated

- Low magnetic field

- No heat delay

- Palletizable

ELECTRO-PERMANENT MAGNETIC CHUCKS

Different types and sizes of electro-permanent magnetic chucks are available on request. The magnetic clamping plates require only a short current pulse for switching and can be used autonomously. Without further energy consumption, without disturbing connections.

- Force generation by current pulse

- Force compound through one-time energy supply

- No heat delay

- Low residual magnetism

- Extreme holding forces

- Palletizable

ELECTRO-PERMANENT MAGNETIC CHUCKS WITH POLE EXTENSIONS

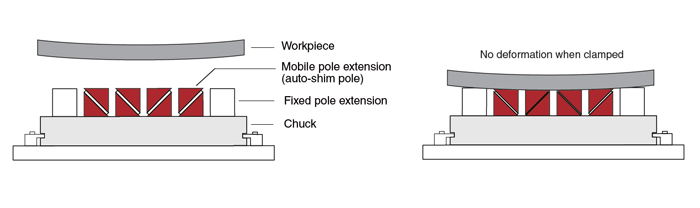

The functional principle

Assembly without tools using the built in threaded rod in the magnetic chuck.

The nominal holding force is transferred to the workpiece through the pole extension.

The fixed pole extension acts as a rigid support surface, while the movable pole extension compensates for a potential deformity of the workpiece up to 6 mm.

Electro-permanent magnetic chucks with square pole clamping system like f.ex. the electro-permant magnetic plate SPQX can be enlarged with mobile and fexed pole extensions. They adapt to the workpiece and hold it securely. The points of contact between magnetic chuck and workpiece can be individually defined.

Pole extension enable holes through the workpiece without damaging the magnetic chuck. Due to the higher locating surface and the maximum accessibility even complex five-side machining can be done.

Electro-permanent magnetic chucks with pole extension enable:

- Evenly distributed magnetic force

- Distortion-free clamping

- Support of uneven workpieces

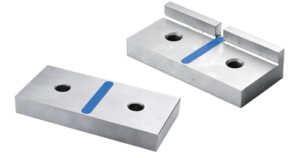

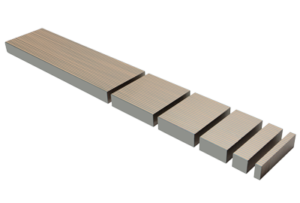

POLE EXTENSIONS

Fixed pole extenions

Mobile pole extensions

Mobile and fixed pole extensions on the square pole clamping system allow the clamping of wavy and warped metal parts. They adapt to your workpiece and clamp it safe.

The points of contact between magnetic plate and workpiece can be defined individually. Also drill through and editing of inside edges of magnetically clamped workpieces is possible.

In no time, it’s possible to add or remove pole extensions – so each workpiece has its individual fixture in a few steps

For the five-side machining, the workpiece can be exempted with pole extensions.

Our polar extensions are made of high quality steel and have the best magnetic flux properties – technically perfect and durable

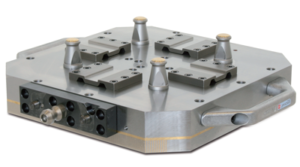

PALLETIZING MAGNETIC CHUCKS

Round palletizing magnetic chuck

Automation has also become indispensable in mechanical processing.

To keep machine downtimes as low as possible, palletizing and zero-point clamping systems are used on EDM, milling and grinding machines. This allows the user to clamp the workpiece already outside the machine, so that a stock of clamped workpieces can be created for the machining machine. External clamping takes place on pallets, which can be picked up in the machine with repeat accuracy.

These pallets are then fed into the machine either manually or automatically. The described magnetic chucks are suitable for use with palletizing systems of all manufacturers.

For the production of self-supporting magnetic pallets, the reference elements can also be installed directly in the magnetic clamping plate. We also supply ready-made magnetic pallets equipped with original clamping and positioning element for all systems.

For heavy machining and large workpieces, we recommend electro-permanent square pole technology, in combination with UniLock-R zero point clamping systems.

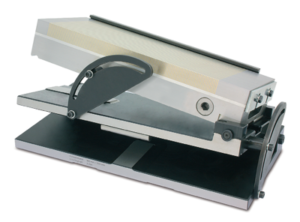

SINE TABLES

Sine tables with integrated magnetic chucks are used to precisely machine angular surfaces on a wide variety of workpieces. With the help of end-gauges, any angle can be set according to the sine principle. Sine tables are mainly used in tool making and fixture construction, where angular precision of 5 seconds is required.

permanent magnetic chucks or electro-permanent magnetic chucks for grinding, milling, EDM or wirecutting. Always with 5 dry precision.

LAMELLA PLATES

Lamella support plates and blocks, are used together with magnetic clamping plates. If parts are very difficult or impossible to clamp on a magnetic chuck due to very low material thickness, three-dimensional structure or poor magnetic properties, lamella plates or lamella blocks offer various additional options.

Pins can be inserted into lamellar plates and contours can be worked into them, or they can be used as bearing surfaces, e.g. for T-shaped parts. Lamella support plates are simply placed or screwed onto the magnetic clamping plate.

Unless otherwise specified, our lamella plates are silver brazed and can therefore be mechanically processed in any way.

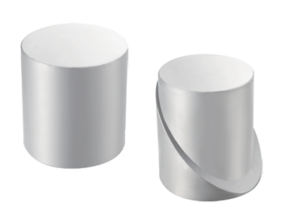

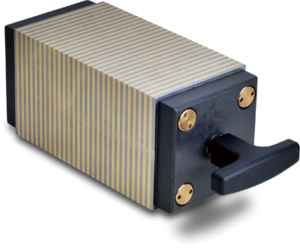

PERMANENT MAGNETIC BLOCKS

Permanent magnetic clamping blocks have 2 or 3 magnetic clamping surfaces which cannot be switched. They are used to clamp very fine parts or materials that are difficult to magnetize, such as high-alloy chrome steel or carbide. After machining, the block with the clamped workpiece can be completely removed from the machine for testing purposes. Clamping blocks are available in standard design and in reinforced design for heavy workpieces. Magnetic clamping blocks are mainly used for grinding, measuring and wire cutting.

Top quality magnetic clamping balls are used to hold parts in optimum working position during laser welding, polishing and assembly. Depending on the workpiece geometry and weight, swivel angles of up to 90° can be set.

CONTROL UNIT

Control unit SPSG-TG

Electro magnetic chucks are operated on pole reversal control units.

These devices make it possible to regulate the holding force and demagnetize workpieces. Pole reversal controllers can be supplied as panel-mounted or table-top units. Attention should be paid to the voltage and power of the solenoid.

SPSG-TG pole reversal control units in table-top version are optimal for retrofitting electromagnetic clamping plates with low installation effort. The device is simply plugged into 230V mains voltage, mains cable with Schuko plug and hand control lever are included.

PERMANENT LIFTING MAGNETS

Permanent lifting magnet SPLM

Lifting magnets for ferromagnetic material, bar stock, cold rolled.

Lifting magnets are available from LxWxH 130 × 70 × 60 mm up to LxWxH 496 × 160 × 140 mm.

- Minimum of 3× safety factor

- Suitable for flat and round material

- Maintenance free design

- Safety device prevent accidental deactivation

- Can be switched off by one hand only

WHAT CAN WE DO FOR YOU?

By using our products and services, our customers increase the productivity of their production by up to 100% and at the same time reduce their production costs to a large extent.