MILLING & DRILLING

Precision clamping equipment as a prerequisite for rational automation

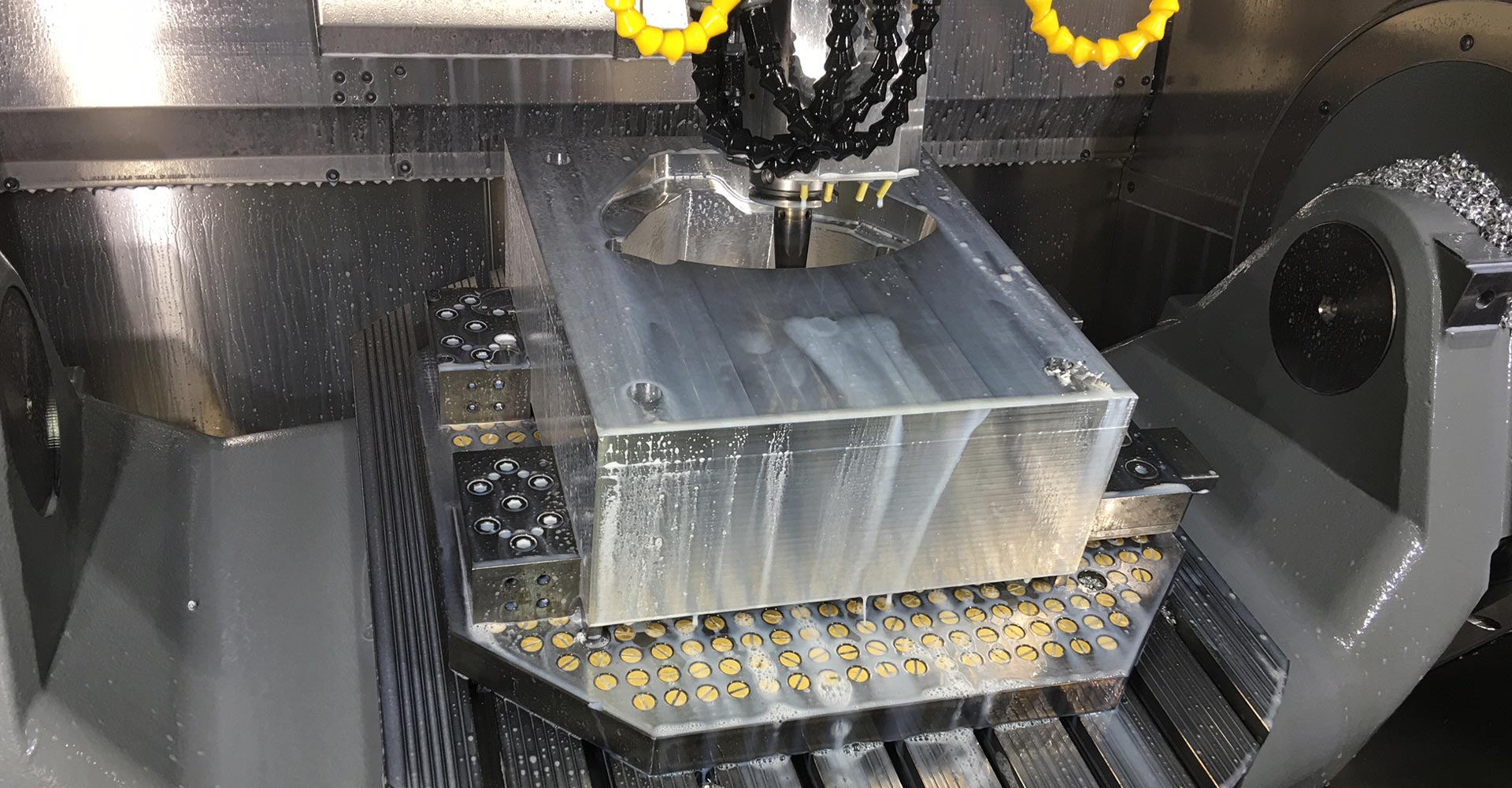

The use of optimum clamping technology is the prerequisite for the highly efficient production process in the field of milling and drilling. Here the focus is on universal clamping systems and multi-sided machining with multiple clamping. The development and manufacture of these and other precision clamping devices has been part of SPREITZER‘s core business for decades. This also includes the extensive field of modular construction systems, special fixtures and rotary unions.

Clamping systems differ not only in their design, size and function, but also in the type of their drive. In addition to mechanical drive, electrical, pneumatic and hydraulic versions are thus also available, which can be integrated into automatic workpiece change intervals. The development and further development of different basic models, which can be modified modularly for each specific application, is therefore the prerequisite for rational production. The following is an excerpt from the product areas

from SPREITZER.

Application in the field of MILLING & DRILLING

WHAT CAN WE DO FOR YOU?

Our products are developed and produced for numerous applications in the manufacturing industry. Our large know-how enables us to offer you the perfect solution for your application. Quality and efficiency are always in the foreground.