CONCENTRICITY GAGES | RUNOUT MEASURING DEVICE

CONCENTRICITY GAGES | RUNOUT MEASURING DEVICE

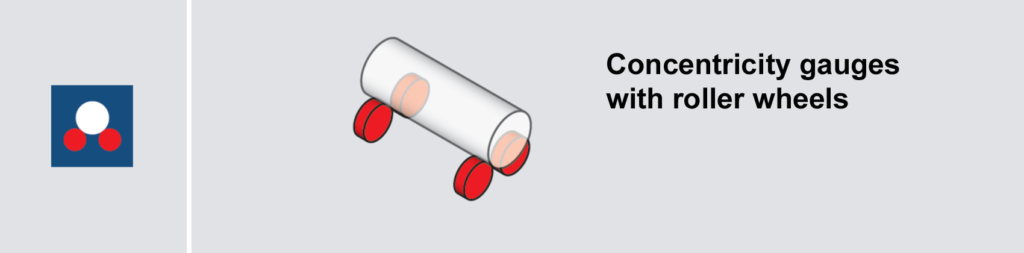

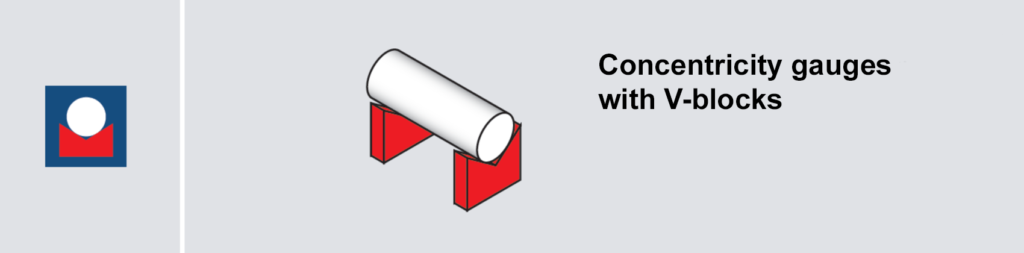

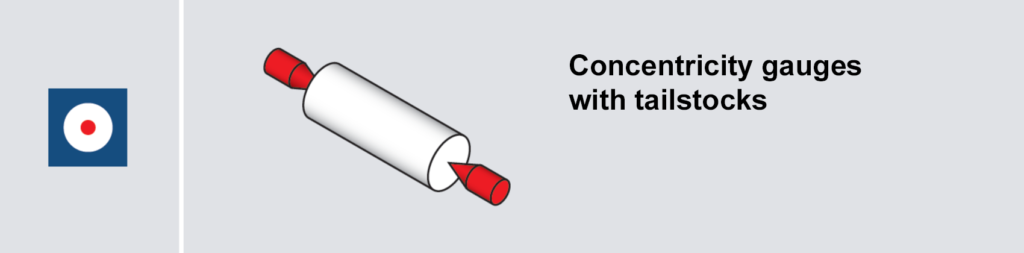

Runout inspection, runout testing right next to the machine. We offer centerless runout testers, bench centres with support prisms, concentricity gages with roll-off blocks and concentricity gauges with tailstocks. The runout test can be performed within 10 seconds without any prior knowledge.

CONCENTRICITY GAUGES | CONCENTRICITY GAGES

Reduces setup and downtime of your expensive processing machine by up to 80%!

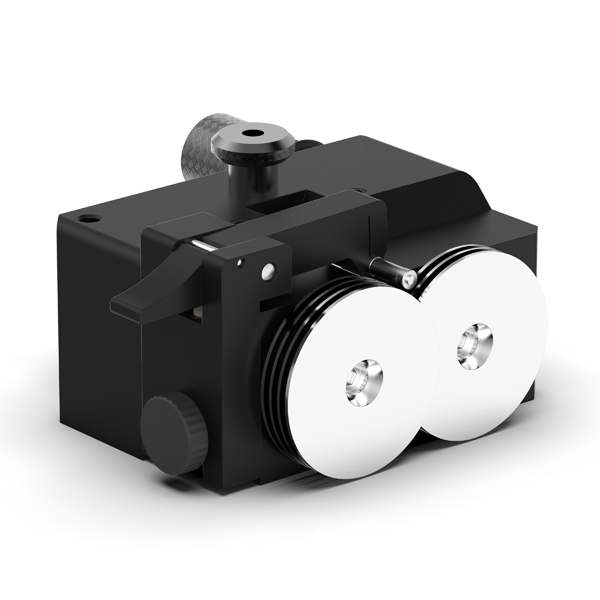

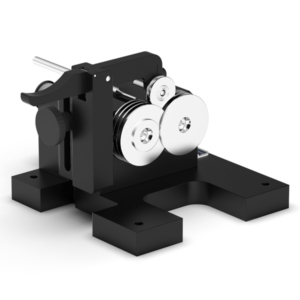

Spreitzer’s concentricity gages offer high flexibility, fast set-up times, high runout accuracy and are suitable for different geometries.

The concentricity gages are used for inspection tasks on external, internal and flat surfaces of rotating parts. The concentricity of a round profile is of considerable importance for the manufacture of shafts, bushings, gear wheels or bearings. Examples from the automotive industry: camshafts, crankshafts, cardan shafts, drive shafts.

With our concentricity gauges, the coaxiality of two or more diameters can be determined and axial runout measurements can be performed. In the RPG, RPG AL RPG mini and RPG micro type, the workpiece is unwound between three rollers without a center. A concentricity of 0.002 mm is achieved. The robust construction with preloaded roller bearings of the support rollers is designed for durability. A diameter range of 0.8 to 240 mm can be covered with the specific product versions.

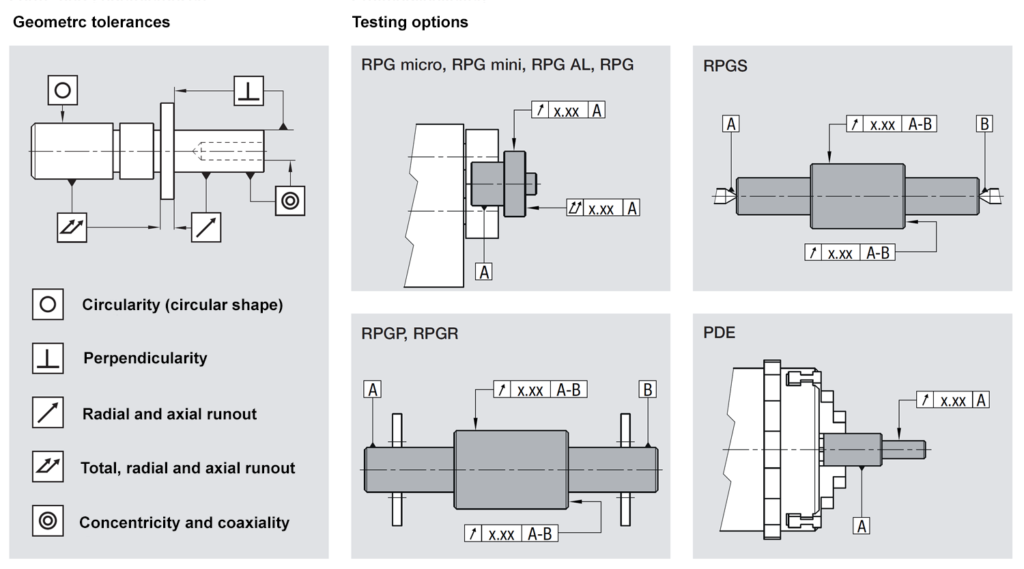

Form and position tolerances | Inspection options

In the measurement technology, concentricity gages occupy a particularly important position. A suitable measuring setup as well as corresponding precision of the concentricity gage are the basis for a precise measurement.

3 PRACTICAL TIPS FOR YOUR SUCCESS

Precise concentricity testing. Within 10 seconds. Without prior knowledge. Directly on the machine.

1. Reduces your internal and external error costs enormously!

2. Reduces the setup and downtime of your expensive CNC machine by up to 80 %!

3. Effective due to simple handling. Indispensable!

WHAT CAN WE DO FOR YOU?

Reduce your manufacturing costs. Measurement tasks precisely solved within seconds.