ALUMESS – CLAMPING AND PALLETIZING SYSTEM

ALUMESS – CLAMPING AND PALLETIZING SYSTEM

ALUMESS – these are modular fixtures for measuring machines and coordinate measuring machines. ALUMESS fixtures are easy to handle, economical and modularly expandable.

ALUMESS – fixtures for measuring machines

Modular fixture for measuring machines, coordinate measuring machines

Easy to handle – economical – modularly expandable

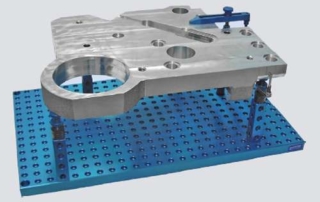

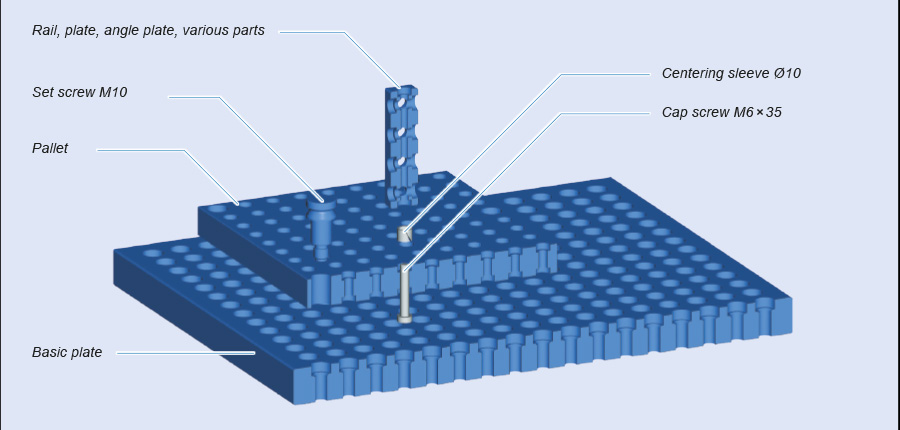

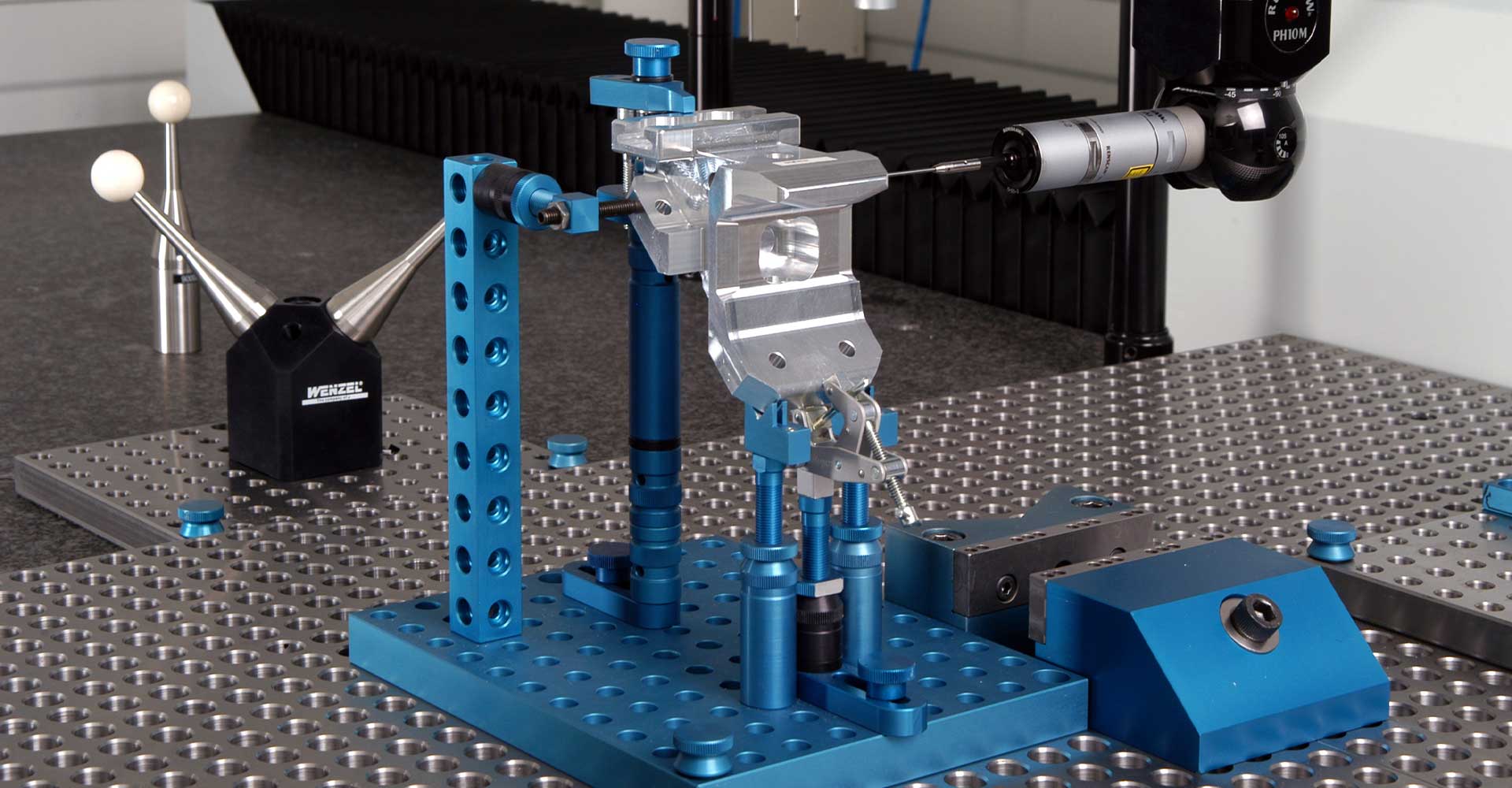

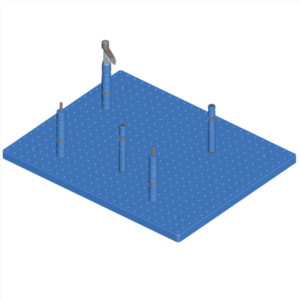

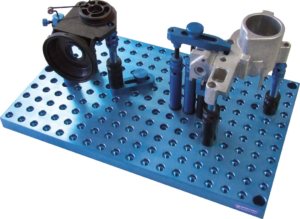

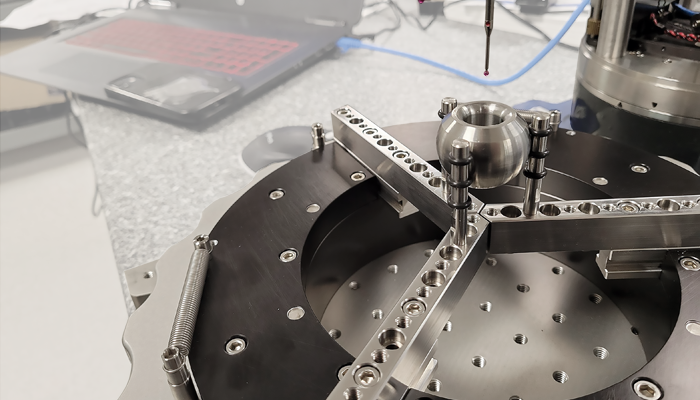

The ALUMESS clamping system is an extremely flexible and comprehensive modular system for fixing workpieces on measuring machines. The clamping system is based on a perforated plate on which the various clamping elements, clamping devices can be positioned. This perforated plate is screwed onto the measuring plate of the measuring machine.

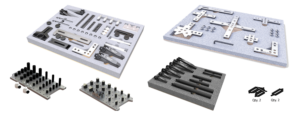

The modular ALUMESS clamping systems enable a positionally accurate and reproducible set-up of clamping devices. They are designed for flexible use at the measuring station, on coordinate measuring machines, on optical measuring devices and in computer tomographs (CT). For a quick introduction to the ALUMESS system family, various starter sets are available, which can be expanded as required. We would be happy to put together a customised kit for you.

Modular concept

Simple, fast and economical The ALUMESS clamping systems consist of many modular elements that can be assembled simply, quickly and economically to form clamping and fixing devices that are accurate in position and reproducible.

Flexible

The ALUMESS clamping systems offer the user maximum flexibility and enable part-specific or customer-specific clamping solutions in the measuring room.

Stable

The components of the different systems are bolted directly together to form a stable, rigid connection. Due to the space-saving design of all components, optimum accessibility to the measuring point is achieved.

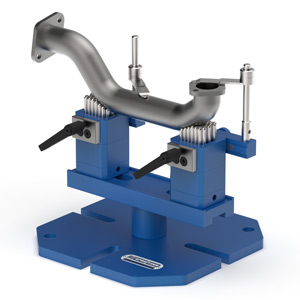

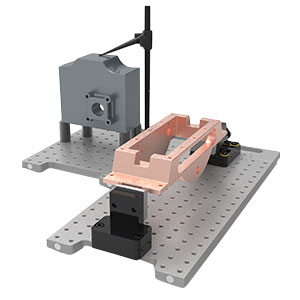

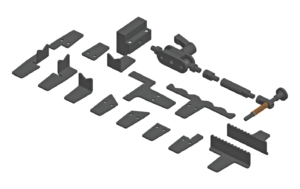

STRUCTURE EXAMPLE

ADVANTAGES AT A GLANCE

- Simplest assembly

- Changeover in seconds

- Flexibly combinable

- User-friendly

- Inexpensive

- Flexible

- Palletizable

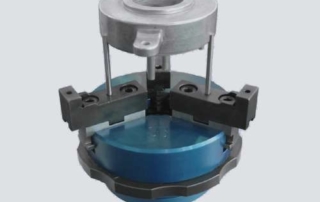

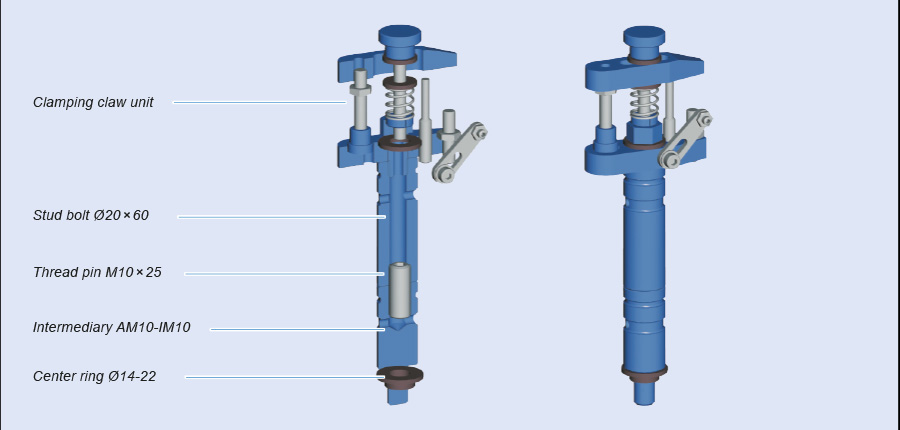

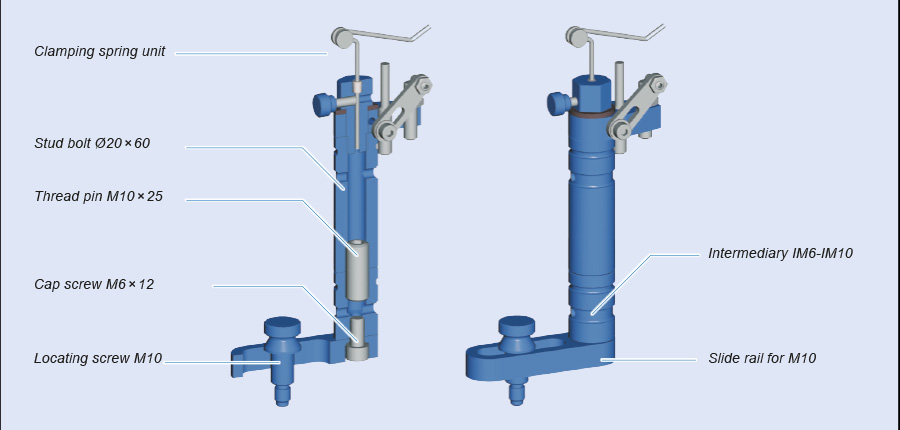

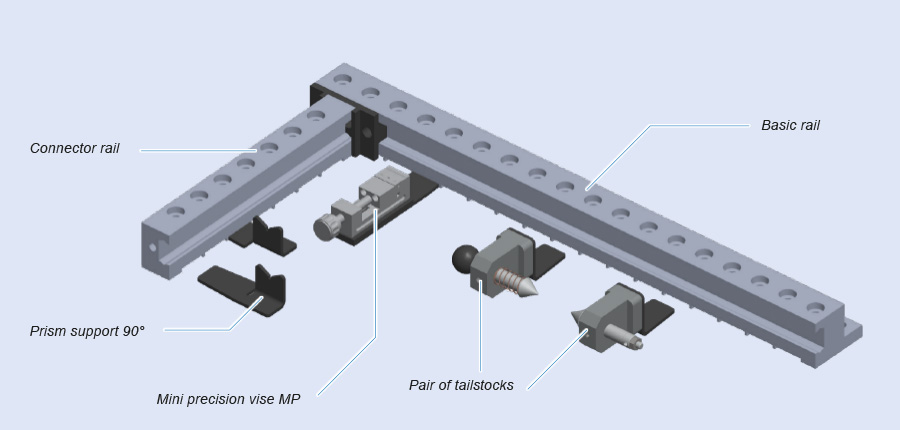

ALUMESS.basic clamping devices

Fixing and clamping of workpieces in a few seconds thanks to the quick-change mechanism of ALUMESS.basic. The clamping system is suitable for tactile measurement at the measuring station or on coordinate measuring machines. The workpieces are fixed in accordance with the contour.

The clamping system for metrology can be combined flexibly and is suitable for tactile measurement, for individual measurement and can be used universally on coordinate measuring machines or at the measuring station.

A detailed system description as well as various basic elements, clamping elements, support and positioning elements can be found in our ALUMESS – Clamping Systems product catalog.

Compatible with:

- ALUMESS.maxx

System description ALUMESS.basic clamping system for measuring machines

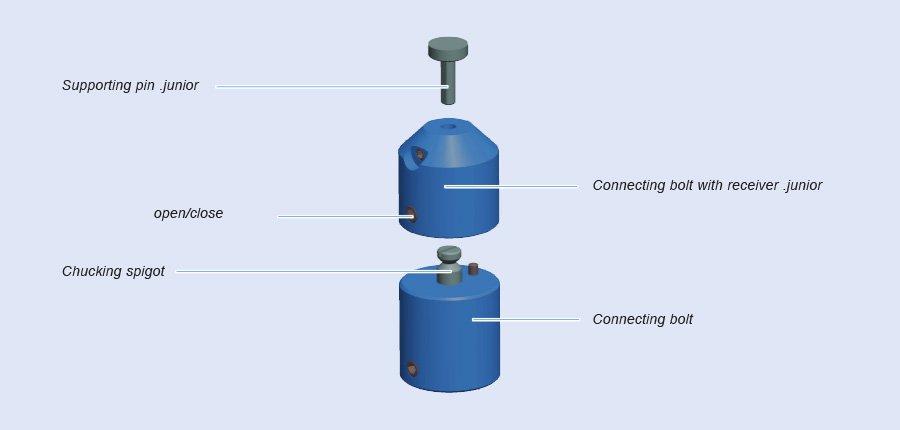

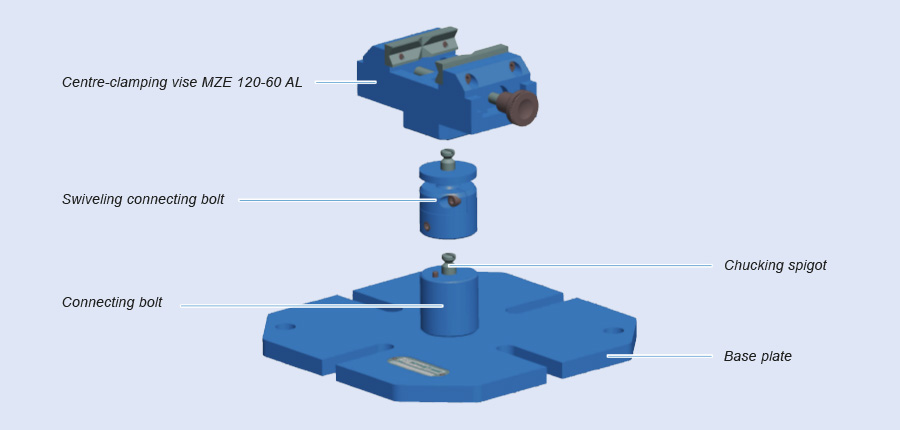

The clamping system with quick-change mechanism for tactile measurement at the measuring station or on coordinate measuring machines. The components can be easily connected to each other with connecting bolts and clamping spigots. With a single Allen wrench, the fixture on the base plate can be changed over in seconds.

- Tactile measurement

- Single measurement

- Universal application at the measuring station or on coordinate measuring machines

System advantages

- Simplest assembly

- Changeover in seconds

- Fixation according to contour

- Flexibly combinable

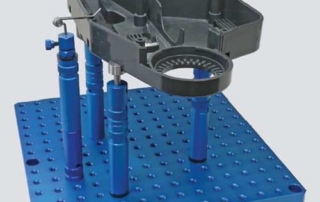

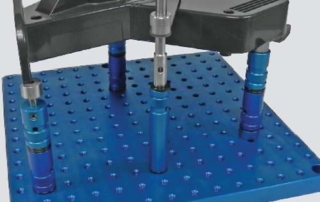

ALUMESS.basic mounting examples

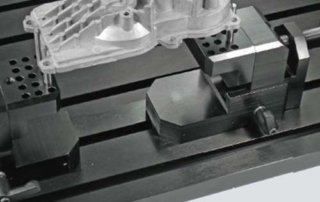

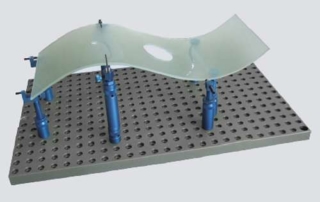

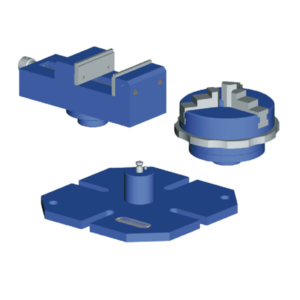

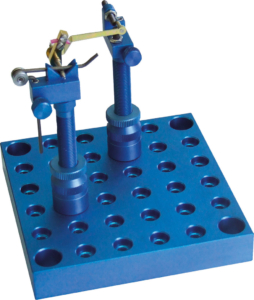

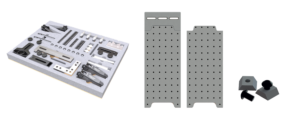

ALUMESS.junior clamping devices

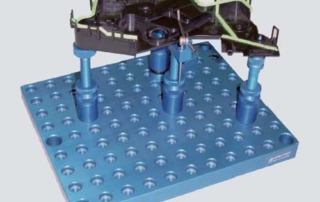

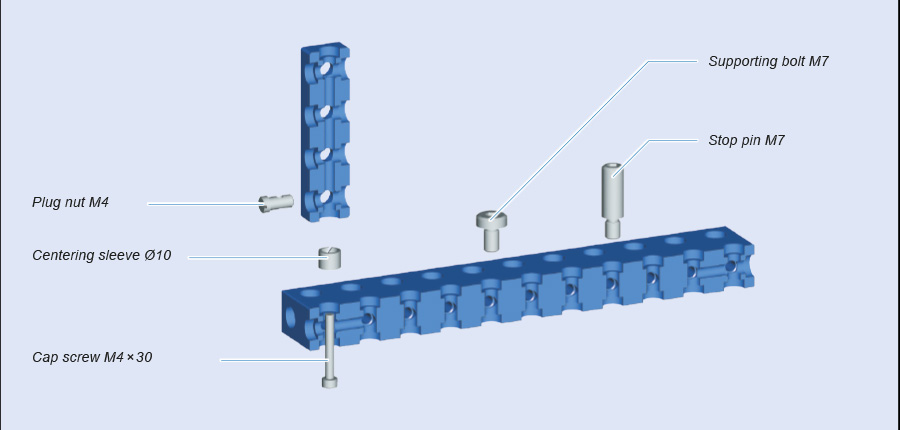

The ALUMESS.junior, the cost-effective entry-level clamping system for series measurement on tactile coordinate measuring machines. The assembly of the components is user-friendly and enables fast clamping of the workpieces to be machined. ALUMESS.junior is suitable for pallet automation.

Different support and positioning elements as well as the necessary clamping elements can be quickly positioned and mounted on the pallets provided with clamping threads. The assembly options for the components are designed to be logical and user-friendly. The clamping system is palletizable.

A detailed description of this clamping device and extensive accessories can be found in the ALUMESS – Clamping Systems product catalog.

Compatible with:

- ALUMESS.maxx

System description ALUMESS.junior Clamping system for measuring machines

ALUMESS.junior offers the user a simple and inexpensive introduction to modular clamping technology for series measurement on tactile coordinate measuring machines. On the pallets, which are exclusively equipped with clamping threads, different support and positioning elements as well as the necessary clamping elements can be mounted flexibly and quickly depending on the application. The assembly options for the components are designed to be logical and user-friendly.

Main application

- Tactile measurement

- Series measurement

- Low-cost entry-level system for coordinate measuring machines

System advantages

- User-friendly

- Inexpensive

- Flexible

- Palletizable

Mounting examples ALUMESS.junior

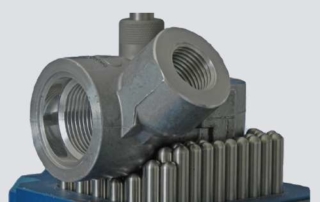

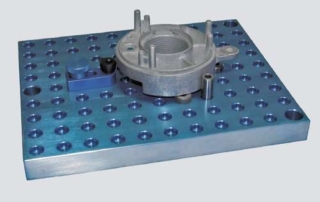

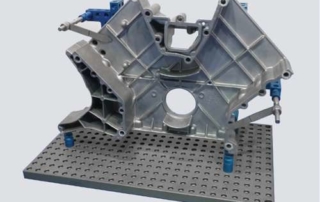

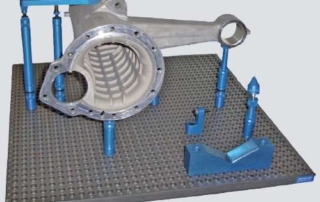

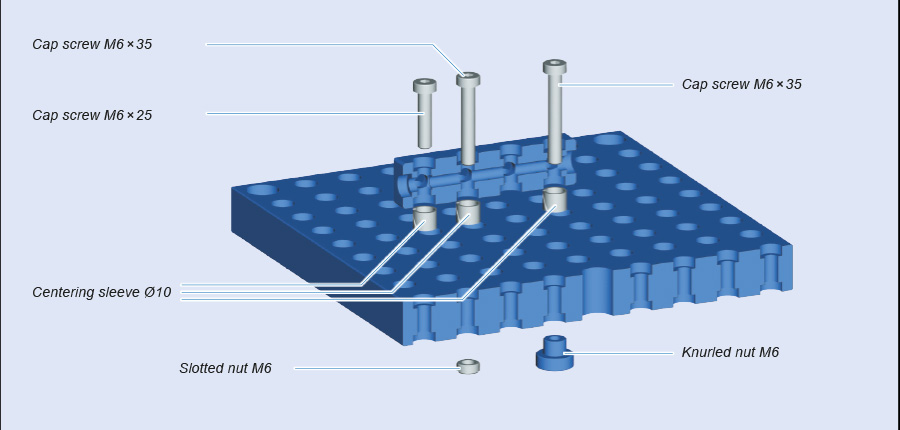

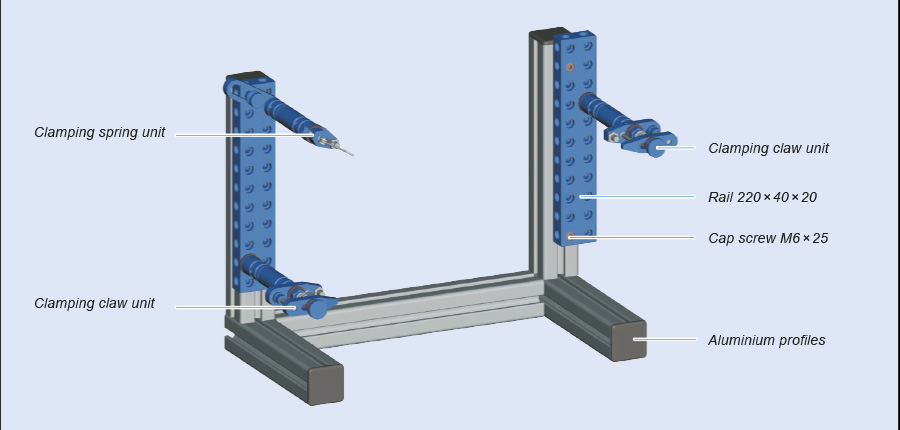

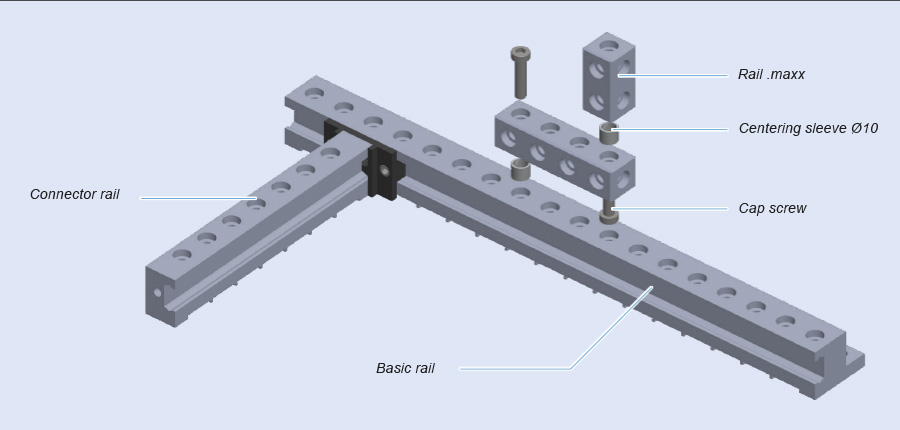

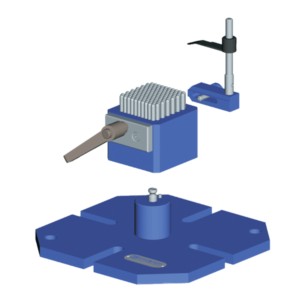

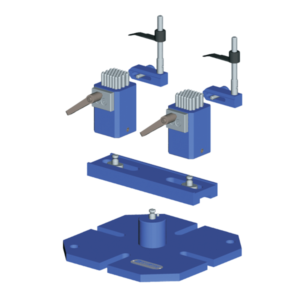

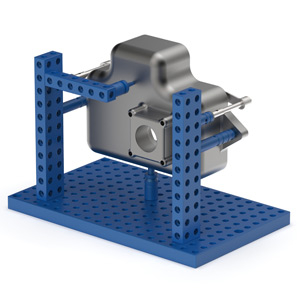

ALUMESS.maxx clamping devices

Stable fixture with a wide range of components. Suitable for series measurement on tactile coordinate measuring machines.

ALUMESS.maxx can also be used for sample or prototype construction, laser marking and laser processing, and as an assembly device.

The clamping system is suitable for pallet automation. The pallets, plates, angles and strips have continuous positioning holes and fastening threads. A comprehensive range of positioner, stop and support elements enables a reproducible, stable and accurate set-up of the clamping device.

Thanks to the maximum reproducibility of the fixtures, only part-specific elements need to be stored for later reuse.

In our ALUMESS – Clamping Systems product catalog you will find a wide range of basic elements, support and positioning elements, clamping elements and accessories.

Compatible with:

- ALUMESS.basic

- ALUMESS.junior

- ALUMESS.optic

System description ALUMESS.maxx clamping system for measuring machines

The ALUMESS.maxx clamping system is mainly designed for universal and flexible use on tactile coordinate measuring machines. Other areas of application include sample and prototype construction, laser marking and laser processing, and use as an assembly device. Positioning holes and fastening threads in the pallets, plates, strips and angles, as well as an extensive range of support, positioning and stop elements, enable a positionally accurate, reproducible and stable setup of any clamping device.

Due to the maximum reproducibility of the fixtures, only part-specific elements need to be stored for later reuse.

Main application

- Tactile measurement

- Series measurement

- Universal use on coordinate measuring machines

System advantages

- Robust and solid

- Maximum universal

- Continuous hole pattern

- Palletizable

Mounting examples ALUMESS.maxx

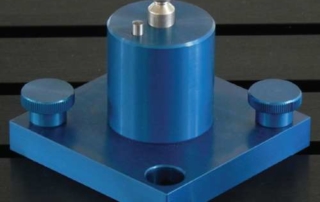

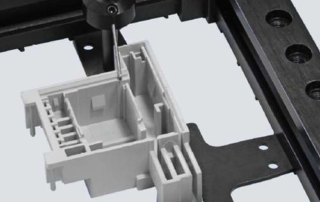

ALUMESS.easyloc clamping devices

ALUMESS.easyloc clamping systems consist of modular, combinable and easy to install, magnetically interlocking quick-swap pallets.

The fixture solutions can be changed quickly. Improve your measuring process and increase your production quantity per shift.

Alumess.easyloc speeds and simplifies inspection using modular, magnetically interlocking quick-swap fixture solutions.

Existing fixtures can be easily adapted and reused.

Elements from ALUMESS.junior and ALUMESS.maxx can be used.

Main application

- Optical and tactile measurement

- Single and series measurement

- Universal use on coordinate measuring machines

- Optical coordinate measuring machines as well as measuring projectors

System advantages

- Application friendly

- For incident and transmitted light

- Modular combinable

- Palletizable

Mounting examples ALUMESS.easyloc clamping device

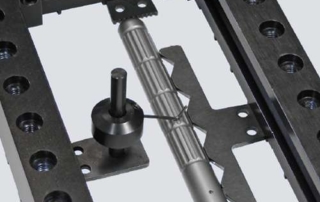

ALUMESS.easyloc tactile measuring with spring-load chuck

ALUMESS.easyloc docking rails with pallets

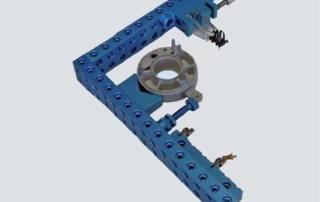

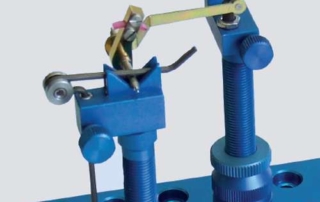

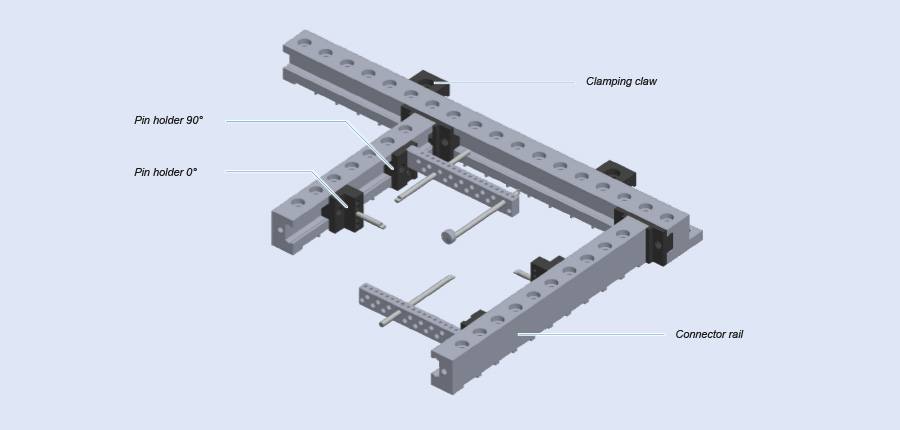

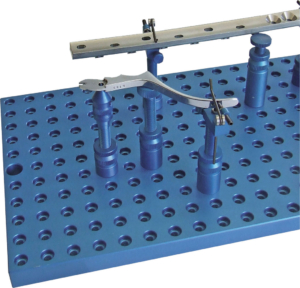

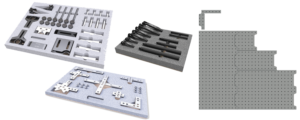

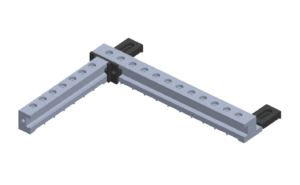

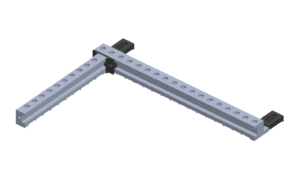

ALUMESS.optic clamping devices

This flexible clamping system is designed for single and serial measurements on optical coordinate measuring machines and measuring projectors. The ALUMESS.optic clamping device can be used on multisensor machines for tactile measurement and for incident light and transmitted light.

The clamping system can be used on multi-sensor machines and with incident and transmitted light for tactile measurement. The clamping device can be palletized. The guide grooves incorporated in base strips and connecting strips allow the clamping frames to be moved in a stepless, scalable manner.

A detailed system description of the clamping system as well as clamping elements, support elements, positioning elements can be found in our ALUMESS – Clamping Systems product catalog.

Compatible with:

- ALUMESS.maxx

System description ALUMESS.optic clamping system for measuring machines

The ALUMESS.optic system is a universal and extremely flexible clamping and fixing system for optical coordinate measuring machines as well as measuring projectors. It can be used with incident and transmitted light and on multisensor machines for tactile measurement. The tensioning frame is infinitely adjustable and scalable via the guide grooves in the base strip and the connecting strip.

Main application

- Optical and tactile measurement

- Single and series measurement

- Optical coordinate measuring machines as well as measuring projectors

System advantages

- Changeover in seconds

- For incident and transmitted light

- Palletizable

Mounting examples ALUMESS.optic clamping device

ALUMESS.xray clamping devices

ALUMESS.xray the clamping system for industrial computer tomography, 3D X-ray measuring technology (CT). Easy mounting, combinable, x-ray transparent, suitable for individual and series measurement.

Elements from ALUMESS.basic, ALUMESS.junior and ALUMESS.easyloc can be used.

Main application

- 3D X-ray metrology

- Single and series measurement

- Universal application in industrial computed tomography

System advantages

- Simplest assembly

- Changeover in seconds

- X-ray banner

- Flexibly combinable

WHAT CAN WE DO FOR YOU?

By using our products and services, our customers increase the productivity of their production by up to 100% and at the same time reduce their production costs to a large extent.