CENTRE-CLAMPING VISES | COMPACT VISES | DOUBLE VISES | AUTOMATION VISES

CENTRE-CLAMPING VISES | COMPACT VISES | DOUBLE VISES | AUTOMATION VISES

Versatile clamping solutions for modern machining centers. Our centric clamps, self-centering vises, compact clamps, double clamps as well as automation vises and alternative clamping technology components have been regarded for years as innovative and powerful solutions on state-of-the-art machining centers. We are ready for your requirements.

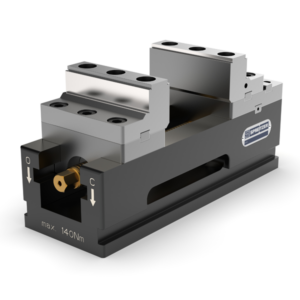

CENTRE-CLAMPING VISES | CENTRIC VISES

The compact mechanical, pneumatic, hydraulic as well as electromechanical centre-clamping vises enable the exact machining of workpieces to the specified axis of symmetry or rotation.

Our presence on the market since 1983 and the experience we have gained as a result enable our customers to access the unique variety of sizes and construction variants on the market.

SPREITZER self-centering vises are used as a high-quality solution for conventional and CNC-controlled manufacturing tasks on various machine tools as well as production systems.

The best centre-clamping vises for your application since 1983.

+ Our centric vises at a glance

- Mechanical

- Pneumatic

- Hydraulic

- Electromechanical

- Available jaw widths 15 – 160 mm

- Available lengths 50 – 500 mm

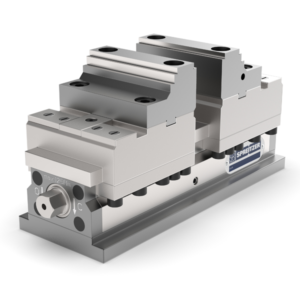

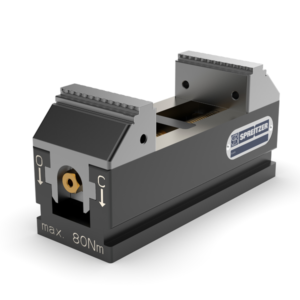

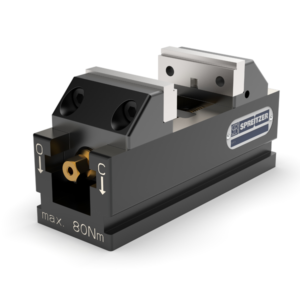

COMPACT VISES | SINGLE STATION VISES

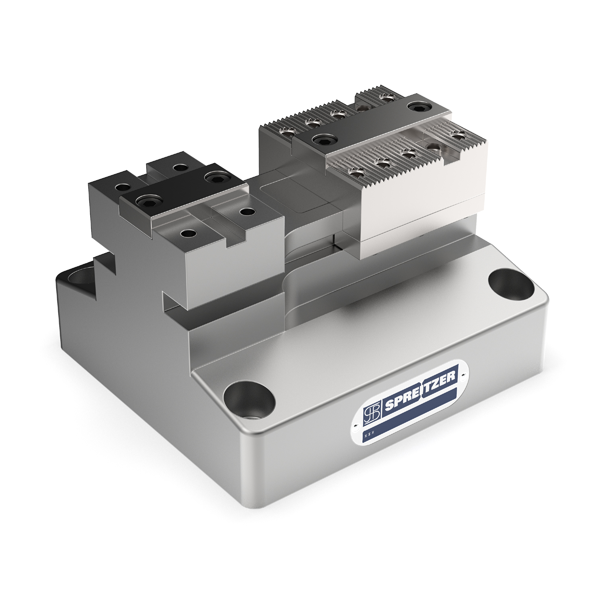

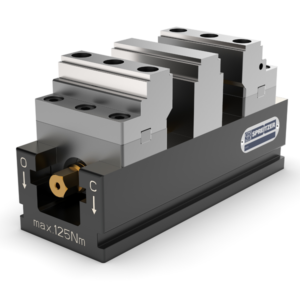

DOUBLE VISES | DOUBLE CLAMPING VISES

With the help of our double vises, two workpieces are clamped securely and precisely against a central fixed stop. Due to the special bearing of the spindle, workpieces with a length difference of up to 2 mm can be accommodated.

+ Strengths

- Clamping of two workpieces against fixed stop

- Large clamping width due to reversible top jaws

- Highest flexibility

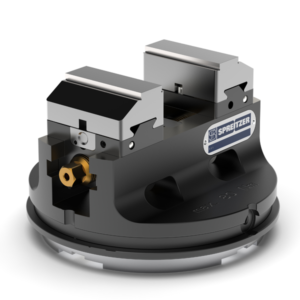

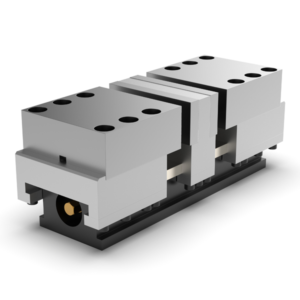

AUTOMATION VISES

SPREITZER offers clamping solutions for automation systems. The mounting hole pattern on the underside of our centre-clamping vises, compact vises, double vises enable an easy mounting on standard palletizing systems, zero-point systems and reference systems. Furthermore we offer completely integrated versions – automation vises – for automation systems of different manufacturers. The base body of the vise is designed with the contour of the resp. pallet gripper / gripper system.

Examples for automation vises:

WHAT CAN WE DO FOR YOU?

By using our products and services, our customers increase the productivity of their production by up to 100% and at the same time reduce their production costs to a large extent.