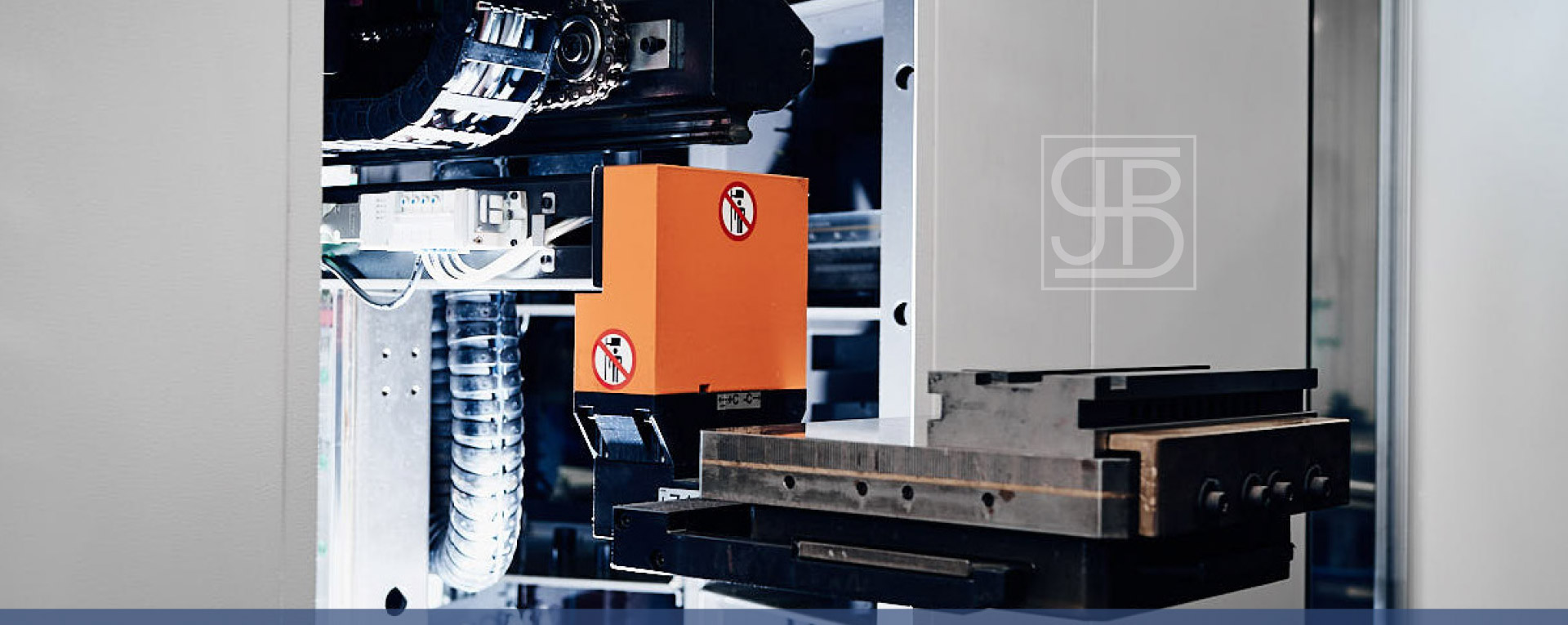

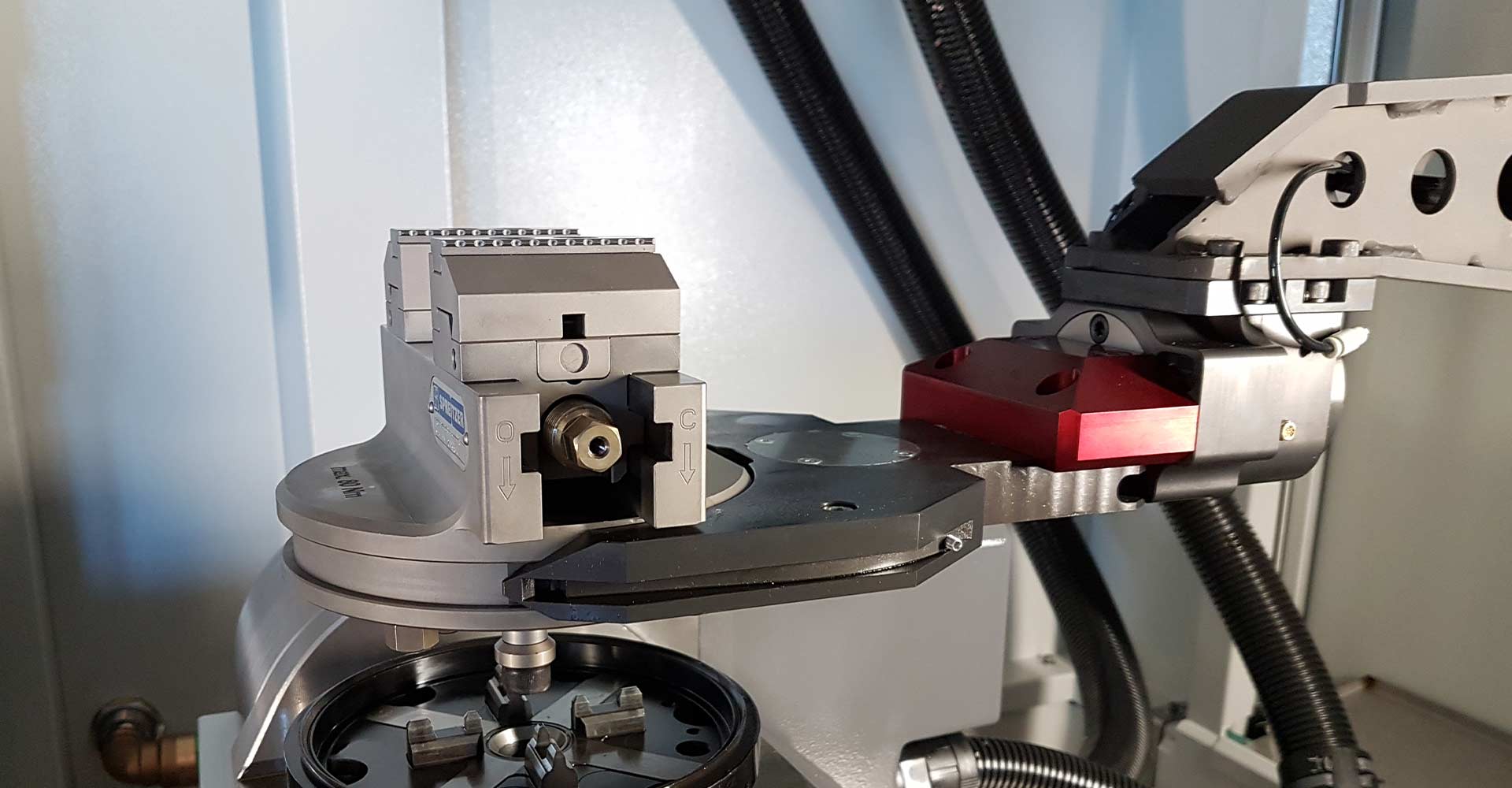

AUTOMATION

Clamping technology in automation

In the field of automation, clamping techniques are required which must perform an independent but fully integrated function within the automatic manufacturing process. This concerns a variety of specific designs with different modes of action, which must correspond to the respective machining technology. But also special fixtures and universal clamping systems are of concern here.

The units developed and produced by Spreitzer meet the highest demands and are adapted to the latest state of automation.

Applications AUTOMATION

WHAT CAN WE DO FOR YOU?

Our products are developed and produced for numerous applications in the manufacturing industry. Our large know-how enables us to offer you the perfect solution for your application. Quality and efficiency are always in the foreground.