MULTI-AXES MACHINING

MULTI-AXES MACHINING

We offer suitable solutions in the field of multi-sided machining that are as varied as they are diverse. Whether simultaneous palletizing of workpiece carriers or universal quick-change systems for high-precision positioning – we are ready for your requirements.

The hydraulic centering, clamping and part unit is a compact fixture unit that holds workpiece fixtures as well as workpiece or fixture pallets via corresponding feed pins. The high-precision positioning, radial indexing, positive clamping and large clamping force characterize this system. There are different areas of application:

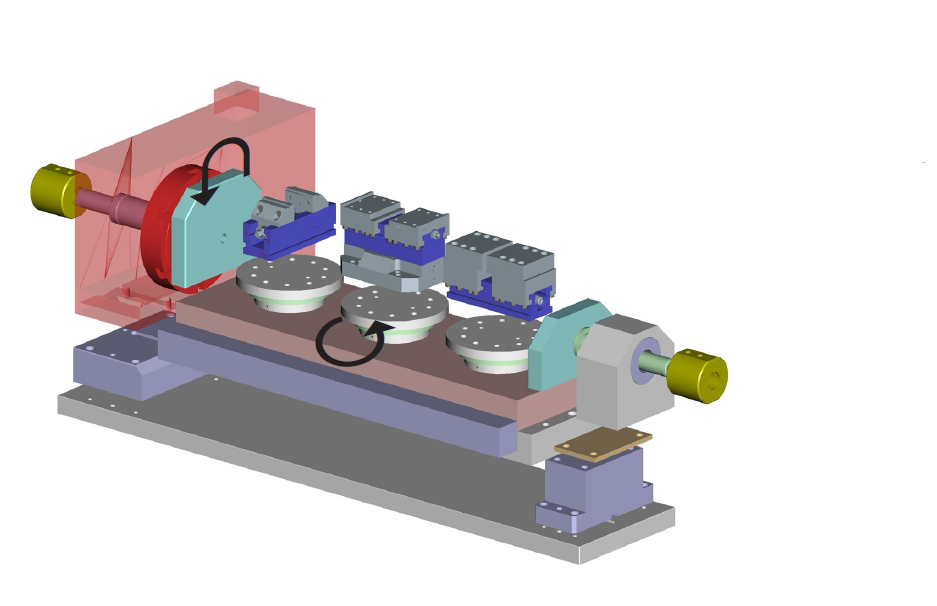

Multi-axes machining with multiple clamping on clamping bridge

Multi-axes machining with multiple clamping

One of the areas of application of hydraulic centering, clamping and part units is the 5- and multi-axes machining of workpieces with simultaneous palletizing of the workpiece carriers. The fixture consists of a clamping bridge between two mounting cheeks, into which the fixture units are integrated. Radial rotation of the workpiece holders in the fixture units with subsequent high-precision positioning and clamping enable complete machining of the workpieces in one operation.

- Economical and efficient on 3-axis machining centers

- Multiple voltage

- Hydraulically actuated, control-independent

- System patent protected

- >|< 0.003 mm

Quick change or palletizing system on a vertical machine

Universal quick change system, palletizing system

The fixture units are used as universal quick-change systems for high-precision positioning, indexing and clamping of workpiece or fixture pallets. Depending on the design, they can be installed directly in the machine table or in base elements provided for this purpose.

- Centering and repeat accuracy of 0.003 mm

- Positive clamping

- Radial indexing

- 5- and multi-axes machining with simultaneous palletizing of the workpiece carriers

- Increase in workpiece accuracy due to complete machining in one operation

- Shorter non-productive time due to pre-equipped workpiece clamping, shorter total machining time

Quick change or palletizing system

on a horizontal machine

Quick change or palletizing system

in connection with a CNC rotary table

WHAT CAN WE DO FOR YOU?

By using our products and services, our customers increase the productivity of their production by up to 100% and at the same time reduce their production costs to a large extent.